●

One control valve for steam or thermal oil heaters, a control cabinet for electric heaters

●

One thermostatic valve for emergency control of the heaters

●

One control cabinet including starters for pumps

●

One alarm panel

The above equipment is built on a steel frame, which can be welded or bolted to its foundation

in the ship. The unit has all internal wiring and piping fully assembled. All HFO pipes are

insulated and provided with trace heating.

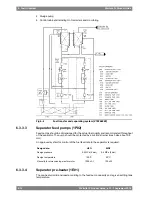

Fig 6-10

Feeder/booster unit, example (DAAE006659)

Fuel feed pump, booster unit (1P04)

The feed pump maintains the pressure in the fuel feed system. It is recommended to use a

screw pump as feed pump. The capacity of the feed pump must be sufficient to prevent

pressure drop during flushing of the automatic filter.

A suction strainer with a fineness of 0.5 mm should be installed before each pump. There

must be a positive static pressure of about 30 kPa on the suction side of the pump.

Design data:

6-26

Wärtsilä 32 Product Guide - a21 - 7 September 2016

Wärtsilä 32 Product Guide

6. Fuel Oil System

Summary of Contents for WARTSILA32

Page 18: ...This page intentionally left blank...

Page 72: ...This page intentionally left blank...

Page 130: ...This page intentionally left blank...

Page 150: ...This page intentionally left blank...

Page 186: ...This page intentionally left blank...

Page 204: ...This page intentionally left blank...

Page 210: ...This page intentionally left blank...

Page 216: ...This page intentionally left blank...

Page 238: ...This page intentionally left blank...

Page 246: ...This page intentionally left blank...

Page 248: ...This page intentionally left blank...

Page 251: ......

Page 252: ......

Page 253: ......