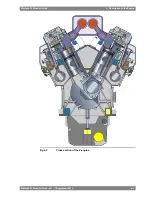

Fig 5-1

Flexible hoses

5.9

Clamping of pipes

It is very important to fix the pipes to rigid structures next to flexible pipe connections in order

to prevent damage caused by vibration. The following guidelines should be applied:

●

Pipe clamps and supports next to the engine must be very rigid and welded to the steel

structure of the foundation.

●

The first support should be located as close as possible to the flexible connection. Next

support should be 0.3-0.5 m from the first support.

●

First three supports closest to the engine or generating set should be fixed supports. Where

necessary, sliding supports can be used after these three fixed supports to allow thermal

expansion of the pipe.

●

Supports should never be welded directly to the pipe. Either pipe clamps or flange supports

should be used for flexible connection.

Examples of flange support structures are shown in Figure 5-2. A typical pipe clamp for a

fixed support is shown in Figure 5-3. Pipe clamps must be made of steel; plastic clamps or

similar may not be used.

5-6

Wärtsilä 32 Product Guide - a21 - 7 September 2016

Wärtsilä 32 Product Guide

5. Piping Design, Treatment and Installation

Summary of Contents for WARTSILA32

Page 18: ...This page intentionally left blank...

Page 72: ...This page intentionally left blank...

Page 130: ...This page intentionally left blank...

Page 150: ...This page intentionally left blank...

Page 186: ...This page intentionally left blank...

Page 204: ...This page intentionally left blank...

Page 210: ...This page intentionally left blank...

Page 216: ...This page intentionally left blank...

Page 238: ...This page intentionally left blank...

Page 246: ...This page intentionally left blank...

Page 248: ...This page intentionally left blank...

Page 251: ......

Page 252: ......

Page 253: ......