15.2.2

Resilient mounting

In order to reduce vibrations and structure borne noise, main engines can be resiliently mounted

on rubber elements. The transmission of forces emitted by the engine is 10-20% when using

resilient mounting. For resiliently mounted engines a speed range of 500-750 rpm is generally

available, but cylinder configuration 18V is limited to constant speed operation (750 rpm) and

resilient mounting is not available for 7L32.

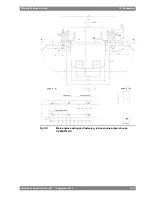

Two different mounting arrangements are applied. Cylinder configurations 6L, 8L, 12V and

16V are mounted on conical rubber mounts, which are similar to the mounts used under

generating sets. The mounts are fastened directly to the engine feet with a hydraulically

tightened bolt. To enable drilling of holes in the foundation after final alignment adjustments

the mount is fastened to an intermediate steel plate, which is fixed to the foundation with one

bolt. The hole in the foundation for this bolt can be drilled through the engine foot. A resin

chock is cast under the intermediate steel plate.

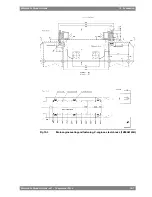

Cylinder configurations 9L and 18V are mounted on cylindrical rubber elements. These rubber

elements are mounted to steel plates in groups, forming eight units. These units, or resilient

elements, each consist of an upper steel plate that is fastened directly to the engine feet,

rubber elements and a lower steel plate that is fastened to the foundation. The holes in the

foundation for the fastening bolts can be drilled through the holes in the engine feet, when the

engine is finally aligned to the reduction gear. The resilient elements are compressed to the

calculated height under load by using M30 bolts through the engine feet and distance pieces

between the two steel plates. Resin chocks are then cast under the resilient elements. Shims

are provided for installation between the engine feet and the resilient elements to facilitate

alignment adjustments in vertical direction. Steel chocks must be used under the side and

end buffers located at each corner if the engine.

Fig 15-5

Principle of resilient mounting, W6L32 and W8L32 (DAAE048811)

Wärtsilä 32 Product Guide - a21 - 7 September 2016

15-11

15. Foundation

Wärtsilä 32 Product Guide

Summary of Contents for WARTSILA32

Page 18: ...This page intentionally left blank...

Page 72: ...This page intentionally left blank...

Page 130: ...This page intentionally left blank...

Page 150: ...This page intentionally left blank...

Page 186: ...This page intentionally left blank...

Page 204: ...This page intentionally left blank...

Page 210: ...This page intentionally left blank...

Page 216: ...This page intentionally left blank...

Page 238: ...This page intentionally left blank...

Page 246: ...This page intentionally left blank...

Page 248: ...This page intentionally left blank...

Page 251: ......

Page 252: ......

Page 253: ......