wc_tx004029gb_FM10.fm

45

Rammer

Disassembly and Reassembly

4.3

Draining the Ramming System Oil—BS60 and BS70

Requirements

■

Approved container for drained oil

Background

Lubricating oil is distributed throughout the ramming system by the action of the

rammer. Holes drilled in the piston carry oil from the bottom of the rammer to the

crankcase as the rammer operates. Oil in the ramming system must be maintained

at the correct level to ensure the ramming system operates efficiently.

Procedure

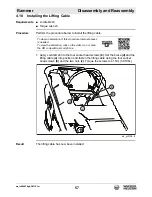

Perform the procedure below to drain the ramming system oil.

1. Tilt the rammer backward until it is resting on the handle.

2. Place a suitable container under the drain plug and remove the drain plug

(a)

.

Note: It may take up to 10 minutes for the oil to drain.

3. Re-install the drain plug and torque it to 54 Nm (40 ft.lbs.).

Note: Dispose of oil in accordance with local environmental regulations.

Result

The ramming system oil has now been drained.

To view an animation of this procedure, internet access

is needed.

To view the animation, click on the video icon or scan

the QR code with a smart phone.

wc_gr012862

a

Summary of Contents for BS 50-4s, BS 50-4As

Page 1: ...Repair Manual Vibratory Rammer 5100018465 01 1015 5 1 0 0 0 1 8 4 6 5 EN...

Page 6: ...wc_tx004061gb_FM10 fm 6 Rammer Foreword...

Page 10: ...Table of Contents Rammer wc_br5100018465_FM10TOC fm 10...

Page 180: ...wc_td000553gb_FM10 fm 180 Rammer Technical Data Notes...

Page 192: ......

Page 193: ......