TAC-7X

MANUAL

Step 4. Refer to Table 6-1. If the TAC Crimper has an

operator-adjustable "G" dimension control, set

the control to setting 6 (the largest wire gauge). If

the setting is not adjustable, perform the GO

/NO-GO tests and adjust to correspond to the

largest wire size.

TABLE 6-1. GO NO-GO DIMENSIONS

Step 5.

Using only hand pressure, extend the arbor as far

to the left as it will go.

Step 6. Using appropriate GO NO-GO gauges, open the

funnel and insert gauges into the indenters to

determine the "G" dimensions.

Conta

ct

Gaug

Setting

Wire Gauge

Go

No-Go

22

1

26

.016

.021

22

2

24

.019

.024

22

3

22

.022

.027

20

4

24

.025

.030

20

5

22

.029

.034

20

6

20

.033

.038

16

1 or 4

20

.029

.034

16

2 or s

18

.033

.038

16

3 or 6

16

.037

.042

Summary of Contents for TAC-7AE

Page 6: ...Figure 1 1 TAC 7X Front View ...

Page 8: ... Figure 1 2 Wire Insertion Through Funnel ...

Page 12: ...Figure2 1 Pneumatic Hook Up ...

Page 14: ... Fiqure 2 4 Track Drop Tube Escapement ESCAPEMENT SYSTEM _ _ _ BR ASSEMBL I TRA ...

Page 18: ... ARBOR COVER PLA TE REMOVED Figure 3 1 Crimp Cylinder Arbor Open ...

Page 20: ... ARBOR COVER PLAT E REMOVED Figure 3 2 Crimp Cylinder Arbor Closed ...

Page 23: ... Crimp Inspection Points Improper Crimps ...

Page 33: ...Figure 6 1 TAC 7X Components ...

Page 34: ...Figure 6 2 Control Box Components Figure 6 2 TAC 7X Components Right View ...

Page 37: ...Figure 6 3 Contact Track Feed Air Adjustments ...

Page 42: ... Figure 6 4 Indenter Plate Removal ...

Page 43: ...HOSE CLAMP CAREFULL Y REMOVE Figure 6 5 Indenter Replacement ...

Page 47: ...Figure 6 6 Indenter Adjustment ...

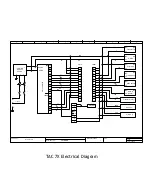

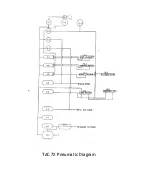

Page 52: ...TAC 7X Pneumatic Diagram ...