2-38

CHAPTER 2 FINISHER UNIT BASIC OPERATION

G.

Tray Operation

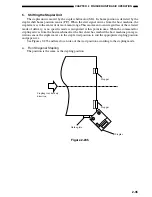

The finisher has two delivery trays. The upper tray is called tray-1 and lower tray is called

tray-2. The tray-1 and tray-2 move up and down independently.

Tray-1 is moved up and down by the tray-1 lift motor (M5), and tray-2 by the tray-2 lift motor

(M10).

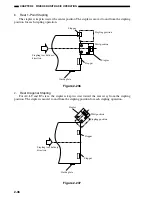

The finisher controller PCB switches the motor driving direction of the tray lift motors (the

motor driver PCB embedded) to control the vertical movement of the trays. When the power is

turned ON, the finisher controller PCB drives the tray lift motors (M5/M10) to return the trays to

their home positions. If the tray is already at the home position, it is moved away from the home

position once, and then returned to that position. If both tray-1 and tray-2 are at the home position,

the above operation is performed for the tray-1 and -2 in this order.

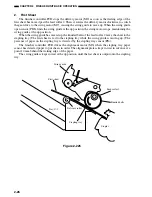

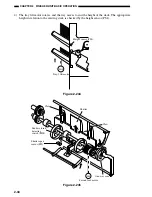

The tray position is detected by the following operation:

The finisher controller PCB counts the clock signal outputted from the tray lift motor (the

motor driver PCB embedded) as soon as the tray starts to move. The finisher controller PCB moves

up and down the tray selected by the host machine so that it is positioned at the delivery slot.

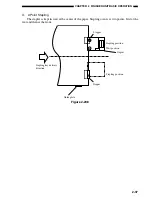

The lower limit of the tray-1 is detected by the tray coming close detecting switch (MS 9). The

finisher controller PCB stops the drive (down) of the tray-1 lift motor (M5) as soon as the tray

coming close detection switch (MS9) turns on.

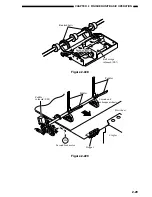

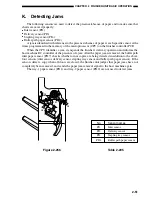

The height of the stack on the tray is identified by the height sensor (PS1), which measures its

distance from the top of the stack. The tray is moved down when the distance between the top of the

stack on the tray and the sensor becomes less than the specific measurement.

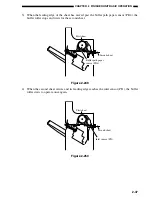

The finisher controller PCB cuts off the +24V power of the tray lift motors (M5/M10) as soon

as the safety zone switch (MS3) turns ON while the shutter and the swing guide are open, stopping

the operation of the finisher.

Summary of Contents for MJ-1027

Page 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Page 5: ...ii ...

Page 9: ...vi ...

Page 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

Page 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

Page 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

Page 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

Page 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Page 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...