3-33

CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION

3.

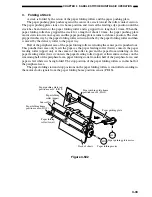

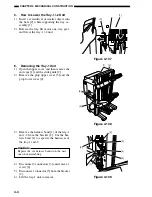

Folding a Stack

A stack is folded by the action of the paper folding rollers and the paper pushing plate.

The paper pushing plate pushes against the center of a stack toward the roller contact section.

The paper pushing plate starts at its home position and waits at the leading edge position until the

stack has been drawn to the paper folding roller and is gripped for a length of 10 mm. When the

paper folding roller has gripped the stack for a length of about 10 mm, the paper pushing plate

motor starts to rotate once again, and the paper pushing plate returns to its home position. The stack

gripped in this way by the paper folding roller is drawn further by the paper folding roller and then

is moved by the delivery roller to the paper tray.

Half of the peripheral area of the paper folding rollers excluding the center part is punched out.

This punched out area only feeds the paper as the paper feeding roller (lower) contacts the paper

feeding roller (upper) only at the center of the roller to prevent the paper from wrinkling. As the

paper feeding roller (lower) contacts the paper feeding roller (upper) at their entire surfaces on the

remaining half of the peripheral area, paper folding starts from this half of the peripheral area, and

paper is fed while it is being folded. The stop position of the paper folding rollers is in this half of

the peripheral area.

The paper folding start and stop positions on the paper folding rollers is controlled according to

the motor clock signals from the paper folding home position sensor (PI21S).

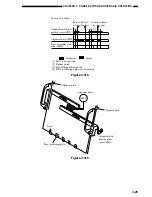

Paper folding

roller (lower)

Paper folding

roller (upper)

Sensor flag

Paper folding home

position sensor

(PI21S)

Paper pushing plate top

position sensor

(PI15S)

Paper pushing plate home

position sensor

(PI14S)

Paper pushing plate

Paper pushing plate motor

Paper folding motor

M2S

M8S

Stack of sheets

Figure 3-502

Summary of Contents for MJ-1027

Page 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Page 5: ...ii ...

Page 9: ...vi ...

Page 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

Page 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

Page 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

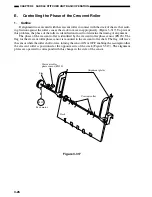

Page 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

Page 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Page 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...