3-17

CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION

B.

Controlling the Inlet Flappers

1.

Outline

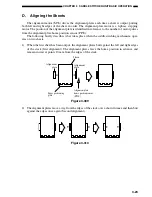

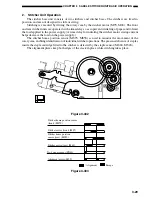

The two flappers mounted at the paper inlet are operated to configure the feed path according to

the size of paper. The flappers are used to enable the following:

1. To detect the passage of the trailing edge of the paper being moved by an appropriate sensor.

2. To prevent the following sheet from butting against the top of the existing stack,

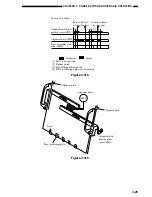

Table 3-301 shows the relationship between sensors and paper sizes.

Sensor

A3/LD

B4/LG

A4-R/LT-R

No.1 paper sensor (PI18S)

Used

Used

Used

No.2 paper sensor (PI19S)

Not used

Used

Used

No.3 paper sensor (PI20S)

Not used

Not used

Used

Table 3-301

Each flapper is driven by its own solenoid.

Table 3-302 shows the relationship between solenoids and paper sizes.

Solenoid

A3/LD

B4/LG

A4-R/LT-R

No.1 paper deflecting plate

OFF

ON

ON

solenoid (SL1S)

No.2 paper deflecting plate

OFF

OFF

ON

solenoid (SL2S)

Table 3-302

Summary of Contents for MJ-1027

Page 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Page 5: ...ii ...

Page 9: ...vi ...

Page 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

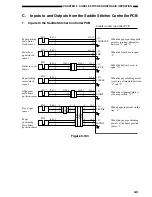

Page 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

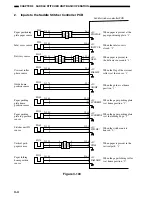

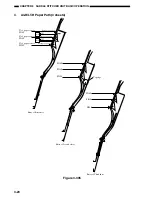

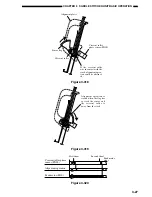

Page 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

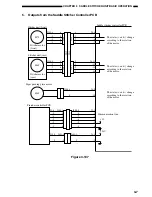

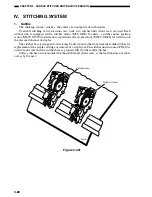

Page 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

Page 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Page 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...