2-1

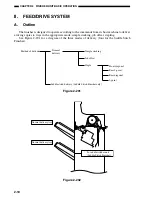

CHAPTER 2 FINISHER UNIT BASIC OPERATION

I.

BASIC OPERATION

A.

Outline

The finisher is designed to deliver copies arriving from its host machine, and its modes of

delivery include simple stacking, job offset

(Note)

, and staple.

All operations involved in these modes are controlled by the finisher controller PCB, according

to the appropriate commands from the host machine.

In the case of the Saddle Stitch Finisher, copies from the host machine may be routed to the

saddle stitcher unit.

Swing guide drive system

Alignment drive system

Stapler drive system

Delivery drive system

Feeder drive system

Shutter drive system

Tray drive system

Tray drive system

Saddle stitcher unit control system

(Saddle Stitch

Finisher)

Control system

Figure 2-101

Note:

The term job offset refers to shifting each sorting job, separating a single

stack into several stacks.

Summary of Contents for MJ-1027

Page 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Page 5: ...ii ...

Page 9: ...vi ...

Page 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

Page 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

Page 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

Page 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

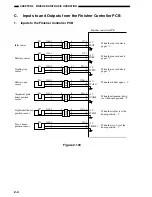

Page 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Page 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...