CHAPTER 2

FINISHER UNIT BASIC OPERATION

I.

BASIC OPERATION .................... 2-1

A. Outline ....................................... 2-1

B. Outline of Electrical Circuitry ...... 2-2

C. Inputs to and Outputs from the

Finisher Controller PCB ............. 2-4

II.

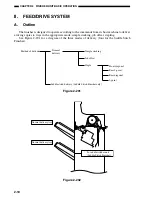

FEED/DRIVE SYSTEM ............. 2-10

A. Outline ..................................... 2-10

B. Type of Delivery Paths ............. 2-15

C. Feeding and Delivering ............ 2-18

D. Job Offset ................................ 2-21

E. Staple Operation ...................... 2-24

F.

Stapler Unit .............................. 2-32

G. Tray Operation .......................... 2-38

H. Detecting the Height of

Stack on the Tray ...................... 2-40

I.

Shutter Operation .................... 2-42

J. Buffer Path Operation .............. 2-46

K. Detecting Jams ........................ 2-51

III. POWER SUPPLY SYSTEM ....... 2-56

1. This chapter discusses the purpose and role of each of the finisher’s functions, and the prin-

ciples of operation used for the finisher mechanical and electrical systems. It also explains the

timing at which these systems are operated.The

symbol in drawings indicates transmission

of mechanical drive, and signals marked by

together with the signal name indicates the

flow of electrical signals.

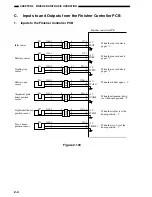

2. In descriptions of digital circuits on the finisher, “1” indicates a high signal voltage level, while

“0” indicates a low signal voltage level. Voltage values differ according to circuit.

A microprocessor is used on the finisher. A description of microprocessor operation is omitted

in this chapter as it is practically impossible to check internal operation of the microprocessor.

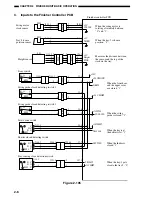

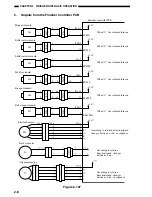

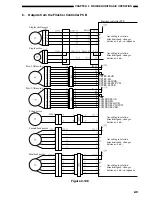

Descriptions in this chapter also assume that PCBs will not be repaired at user sites. For this

reason, descriptions of circuits on PCBs is limited to block diagrams. Two types of block dia-

grams are provided for separate functions: diagrams indicating details from sensors up to input

sections of major PCBs, and diagrams indicating details from the output sections of major

PCBs up the loads.

Summary of Contents for MJ-1027

Page 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Page 5: ...ii ...

Page 9: ...vi ...

Page 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

Page 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

Page 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

Page 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

Page 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Page 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...