6-

CHAPTER 6 TROUBLESHOOTING

07/09

I. ADJUSTMENTS

Note

Before performing each adjustment, make

sure that all covers (incl. those of the finisher

and host machine) are closed. Otherwise, the

power is not supplied to the finisher and the

adjustment may not be performed properly.

A. Electrical System (finish-

er unit)

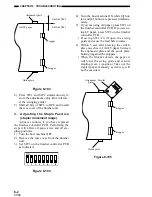

. Adjusting the Height Sensor (PS)

Perform the following adjustments

whenever you have replaced the finisher con

-

troller PCB or the height sensor (PS1).

1) Turn the host machine OFF.

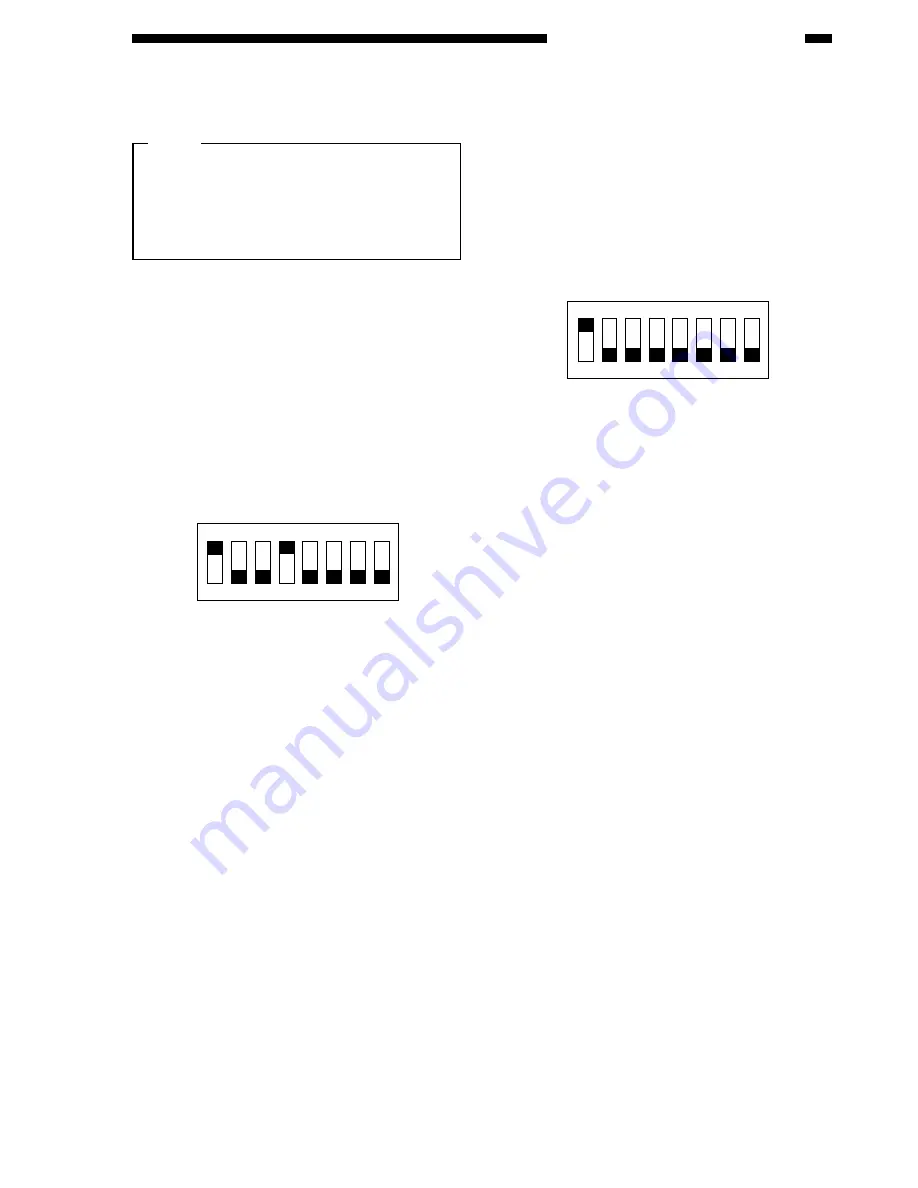

2) Set SW3 on the finisher controller PCB

as indicated.

ON

1

2

3

4 5

6

7

8

Figure 6-0

3) Turn the host machine ON while [0] but-

ton and [8] button are pressed simultane-

ously.

4) Place a paper on the tray.

5) Press SW1 on the finisher controller

PCB. This causes the finisher to execute

automatic adjustment, in which the tray

unit will shift.

• At the end of adjustment, trays will re-

turn to their home positions.

• During adjustment, LED1 flashes. At the

end of adjustment, LED1 turns and re-

mains ON.

• If automatic adjustment fails, the mecha-

nism stops while the tray in question is

being adjusted (at the same time, LED1

turns OFF).

6) Shift all bits on SW3 to OFF, and turn

OFF the host machine once.

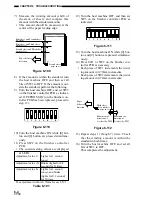

2. Adjusting the Alignment Position

If you have replaced the finisher control

-

ler PCB or if an alignment fault occurs, adjust

as follows. Performing the steps will affect

all paper sizes.

1) Turn the host machine OFF.

2) Remove the rear cover of the finisher

unit.

3) Set SW3 of the finisher controller PCB as

indicated.

ON

1

2

3

4 5

6

7

8

Figure 6-02

4) Turn the host machine ON while [0] but-

ton and [8] button are pressed simultane-

ously.

5) If you are using A4 paper, press SW1 on

the finisher controller PCB. If you are us

-

ing LT paper, press SW2 on the finisher

controller PCB.

• Pressing SW1/2 will open the swing

guide and cause the alignment plate to

move to A4/LT positions.

6) Place 10 sheets of A4/LT paper between

the alignment plate and the guide plate,

butting them against the stoppers.

7) Press SW1 or SW2 on the finisher con

-

troller PCB, and butt the alignment plate

against the sheets.

• Pressing SW1 will shift the alignment

plate to the front in 0.35 mm increments.

• Pressing SW2 will shift the alignment

plate to the rear in 0.35 mm increments.

Summary of Contents for MJ-1027

Page 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Page 5: ...ii ...

Page 9: ...vi ...

Page 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

Page 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

Page 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

Page 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

Page 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Page 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...