6-3

CHAPTER 6 TROUBLESHOOTING

07/09

4. Adjusting the Buffer Roller Wind-

ing Amount

Perform this adjustment in the following

instances:

a. When the finisher controller PCB or the

EEPROM (Q2) on the finisher controller

PCB has been replaced

b. When something causes the winding

amount to fluctuate

The "winding amount" is the amount of

difference between the First and Second

sheets wound onto the buffer roller de-

vice in the feed direction.

Paper delivery

direction

First sheet

Second sheet

Third sheet

Winding

amount

Figure 6-07

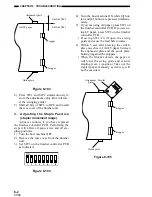

1) Turn the host machine OFF.

2) Set SW3 on the finisher controller PCB

as indicated.

ON

1

2

3

4 5

6

7

8

Figure 6-08

3) Turn the host machine ON while [0] but-

ton and [8] button are pressed simultane-

ously.

4) Set the mode setting on the host machine

to "1" and the number of originals (A4 or

LT) to "3" in the staple mode.

5) Press the copy start key.

• Copying starts, three sheets for the first

copy are output as a stack on the staple

tray, and copying stops with the copies

held at the delivery roller.

6) Remove the stack of sheets from the fin

-

isher delivery taking care to prevent the

offset of the output sheets from changing.

7) If the stapling position is correct, set all

bits on SW3 to OFF to end the adjust-

ments. If you need to change the stapling

position, on the other hand, go to the next

step.

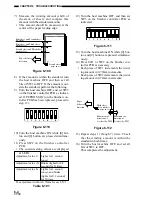

8) To suit the position of the staple on the

paper, press SW1 or SW2 on the finisher

controller PCB as many times as neces-

sary.

• Pressing SW1 will shift the stapling posi-

tion to the front in 0.3 mm increments.

• Pressing SW2 will shift the stapling posi-

tion to the rear in 0.3 mm increments.

Shift by SW2

Shift by SW1

Feeding direction

Staple

Paper

291±2mm (A4)/

273±2mm (LT)

Figure 6-06

9) Press SW1 and SW2 simultaneously.

• This will open the swing guide, and

cause the feed belt to rotate. Placement of

one sheet of A4/LT paper will cause the

finisher to start stapling.

10) Check the stapling position. If good, set

all bits of SW3 to OFF. If re-adjustments

are necessary, go back to Step 8.

Caution:

The settings held by the finisher controller

PCB are changed as soon as SW1 or SW2

is pressed. As such, to recover the previous

settings after the press, you must press the

other of the two switches as many times as

you pressed previously.

Summary of Contents for MJ-1027

Page 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Page 5: ...ii ...

Page 9: ...vi ...

Page 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

Page 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

Page 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

Page 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

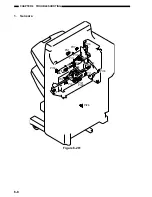

Page 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Page 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...