6-28

CHAPTER 6 TROUBLESHOOTING

14. Faulty swing motor (related to PI20)

15. Faulty tray-1 lift motor (related to PI8)

16. Faulty tray-2 lift motor (related to PI25)

Checks

Check the swing motor clock

sensor. Is the sensor normal?

Does the voltage of the swing

motor between J11-6 and -7

on the finisher controller PCB

reach 24 V at a specific

rotation timing?

Cause

Swing motor clock

sensor (PI20)

Finisher controller PCB

Step

1

2

Yes/No

No

No

Yes

Action

Replace the sensor.

Replace the finisher

controller PCB.

Check the wiring from

the motor to the

finisher controller

PCB. If normal,

replace the motor.

Checks

Check the tray-1 home

position sensor. Is it normal?

Check the tray-1 lift

mechanism. Is the mechanism

normal?

Is the tray-1 lift motor

supplied with 24 VDC by the

finisher controller PCB as

soon as the tray is driven?

Check the wiring from the

finisher controller PCB to the

tray-1 lift motor. Is the wiring

normal?

Cause

Tray-1 home position

sensor (PI8)

Tray-1 lift mechanism

Finisher controller PCB

Wiring

Tray-1 lift motor (M5)

Step

1

2

3

4

Yes/No

No

No

No

No

Yes

Action

Replace the sensor.

Correct the

mechanism.

Replace the finisher

controller PCB.

Correct the wiring.

Replace the tray-1 lift

motor.

Checks

Check the tray-2 lift

mechanism. Is the mechanism

normal?

Is the tray-2 lift motor

supplied with 24 VDC by the

finisher controller PCB as

soon as the tray is driven?

Check the wiring from the

finisher controller PCB to the

tray-2 lift motor. Is the wiring

normal?

Cause

Tray-2 lift mechanism

(PI25)

Finisher controller PCB

Wiring

Tray-2 lift motor (M10)

Step

1

2

3

Yes/No

No

No

No

Yes

Action

Correct the

mechanism.

Replace the finisher

controller PCB.

Correct the wiring.

Replace the tray-2 lift

motor.

Note :

If the tray cannot be lowered because it makes contact with something under the Finisher, this error occurs.

Therefore, tell the users not to place anything under the tray.

Summary of Contents for MJ-1027

Page 1: ...SERVICE MANUAL FINISHER MJ 1027 1028 File No SME040041A0 R04102169300 TTEC Ver01_2007 09 ...

Page 5: ...ii ...

Page 9: ...vi ...

Page 70: ...2 41 CHAPTER 2 FINISHER UNIT BASIC OPERATION Height sensor PS1 Paper Figure 2 240 ...

Page 101: ...3 15 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Figure 3 301 ...

Page 104: ...3 18 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION 2 A3 LD Paper Path 3 sheets Figure 3 303 ...

Page 116: ...3 30 CHAPTER 3 SADDLE STITCHER UNIT BASIC OPERATION Cam Mount Figure 3 404 ...

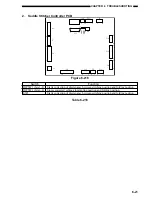

Page 173: ...6 CHAPTER 6 TROUBLESHOOTING II ARRANGEMENT OF ELECTRICAL PARTS A Finisher Unit ...

Page 235: ...2 17 2 HIGASHIGOTANDA SHINAGAWA KU TOKYO 141 8664 JAPAN ...