drill the holes for the fuel lines. Drill the holes with a

1/4” [6.4mm] drill (15/64” [6mm] drill for a better fit).

Coat the inside of the fuselage between the firewall

and former F2, including the back of the firewall, with

fuel proof paint, epoxy or finishing resin.

Note:

The

fuel tank is mounted sideways. In a model of this

type, this will not create a problem; just don’t do any

sustained knife edge flight.

❏

2. Place 1/4” [6.4mm] foam rubber on the tank

floor. Secure the tank to the tank floor with the

#32

rubber bands

included with this kit. Install the tank

and tank floor in the model and glue it into position

with medium CA. The photo at step 1 shows a Great

Planes 16 oz tank with former F1A in position.

Note:

Rubber bands deteriorate over time, so you should

replace them at least once a year.

❏

3. Install fuel and vent lines on the tank and route

them through the holes in the firewall to the location

of your fuel fill valve (see page 57, step 14) and the

muffler pressure fitting. Cut them a couple of inches

longer than needed.

Note:

In the future, when the

tank needs maintenance, cut the top part of F2 away

so the tank can be removed. You will also need to

remove the front canopy, which we mounted with

screws on our prototype.

❏

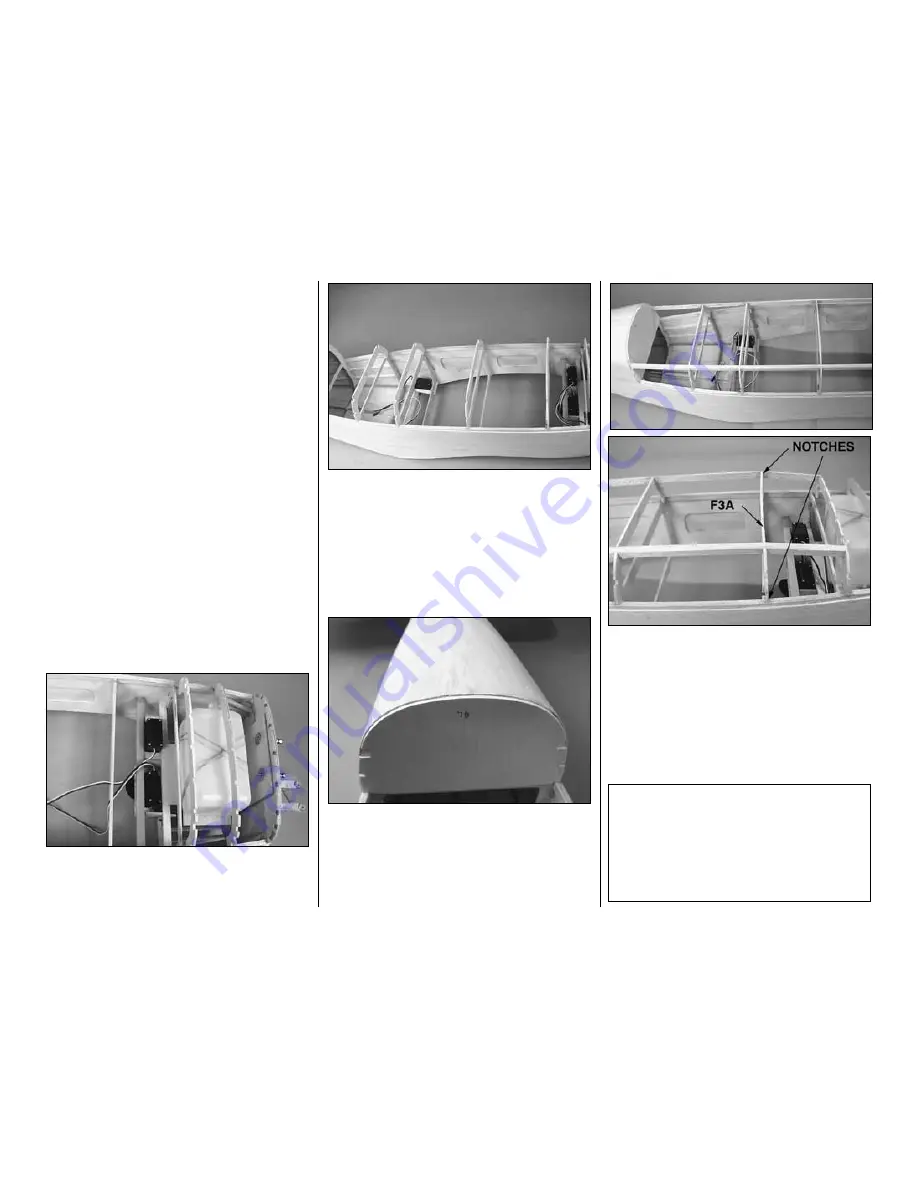

4. Glue the die-cut 1/8” [3.2mm] plywood formers

F1A

and

F2A

in place as shown on the plan. F1A is

positioned 2” [51mm] forward of F2. F2A is

positioned 3/16” [4.7mm] forward of F2.

❏

5. Glue the die-cut 1/8” [3.2mm] plywood formers

F3A

through

F6A

in place as shown on the plan. The

formers are glued to the front of its corresponding

former. If you previously cut slots for the servo wires

in F3, F4 and F5, then cut the needed slots in F3A,

F4A and F5A.

❏

6. If you have not already sanded the turtle deck

to shape then do so now. Remember, sand the 1/16”

[1.6mm] balsa carefully. Fit the die-cut 1/8” [3.2mm]

plywood former

F7D

to the front of F7A. Sand the

edges of F7D so that there is a lip the thickness of

the canopy. When you are satisfied with the fit, glue

F7D to F7A.

❏

7. Make the

canopy base

from two 1/4” x 3/8” x

36” [6.4 x 9.5 x 915mm] balsa sticks. Cut them to fit

between F2A to F7D. The sticks angle down between

F2A and F3A so you will need to cut a notch in the

stick at F3A. Glue the sticks in place, making sure

they are firmly seated in the notches in the formers,

especially at F7D.

T-34B Fact:

One of the Navy’s Mentors

accumulated over 5,000 hours of flying time - a lot

of time for a military aircraft. This aircraft had done

nearly 16,500 landings, 18,000 stalls, 3,400 spins

and 4,600 loops. The Navy decided to test the

service life of the airframe and after 15,000 hours

of testing the Navy declared that the T-34B had no

airframe life limit.

-51-

Summary of Contents for T-34B MENTOR

Page 7: ...7 DIE CUT PATTERNS...