Recheck that the fin is

vertical

in relation to the stab

and that the TE of the fin is

perpendicular

to the

main fuselage stringer. Also check that the TE of the

fin is against the rudder torque rod and that the rod

is in the

center

of the fin TE. Use masking tape to

hold the fin in position until the epoxy is fully cured.

Note:

Be very careful not to get any epoxy on the rudder

torque rod or in the torque rod hole in the stab.

❏

5. Test fit the rudder and elevator and temporarily

hook up the pushrods. Make sure you can move the

controls without any interference or binding. Make

adjustments if necessary.

BUILD THE TURTLE DECK

❏

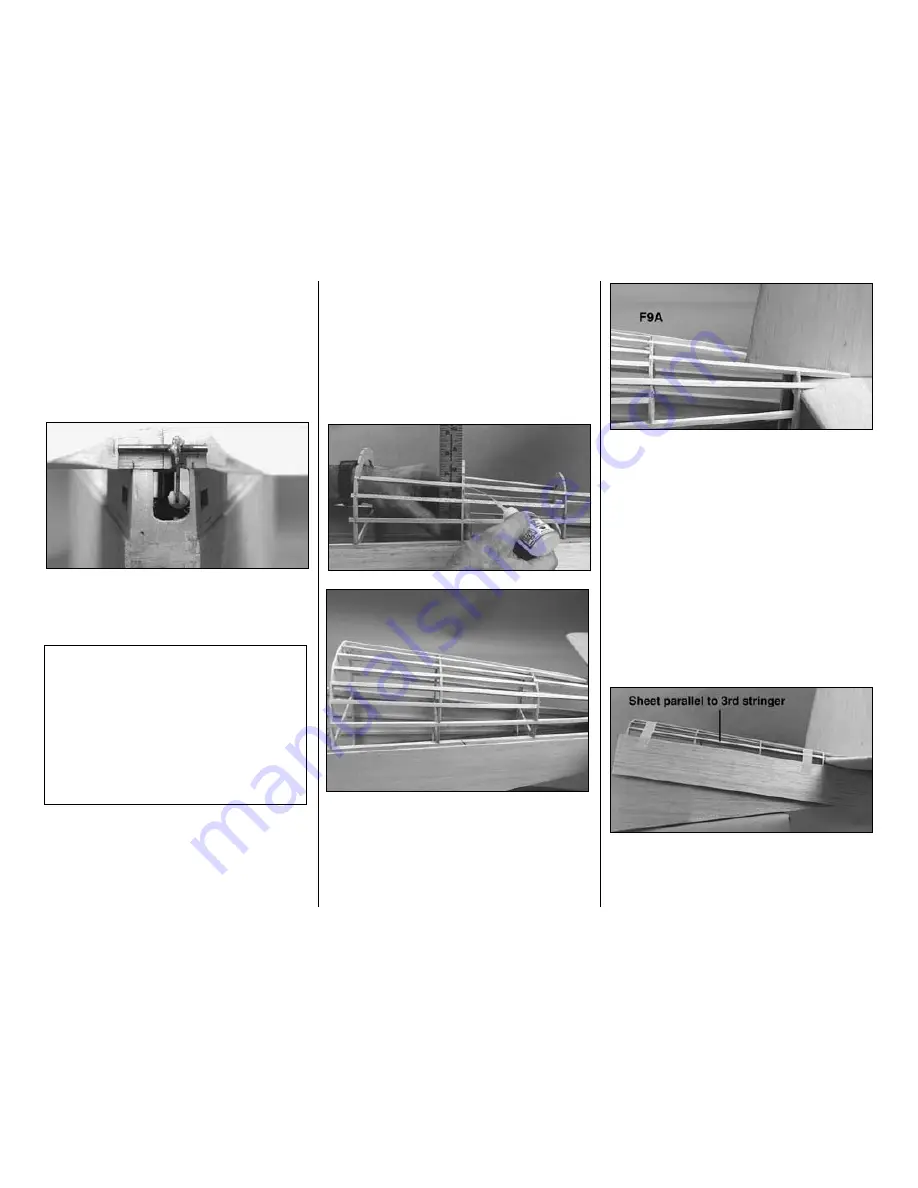

1. Glue the die-cut 1/8” [3.2mm] ply formers

F7A,

F8A

and

F9A

to the tops of their respective formers.

❏

2. Cut the

turtle deck stringers

from seven 3/16”

x 3/16” x 30” [4.8 x 4.8 x 762mm] balsa sticks. Glue

the stringers into the notches of the formers as

shown on the fuselage plan and in the photo. Note

the arrangement of the stringers at F9A.

Important:

Align the formers with a straightedge as

you glue the stringers to them.

❏

3. Sand the stringers and formers so they

blend together.

❏

4. The turtle deck is sheeted with four 1/16”

[1.6mm] balsa sheets–one sheet on the bottom of

each side of the turtle deck and one sheet on the top

of each side of the turtle deck. Examine the four

1/16” x 3” x 24” [1.6 x 76.2 x 610mm] balsa sheets

and set the two softest sheets aside to be used for

the top.

Caution:

To save weight in the aft end of the model,

the turtle deck is sheeted with 1/16” [1.6mm] balsa.

Be careful installing the sheeting so that it will not

require an excessive amount of sanding.

❏ ❏

5. Cut one of the bottom turtle deck sheets to a

length of 21-1/2” [546mm]. Position the sheet on the

left side of the turtle deck so the top edge contacts

the bottom of the stab and is parallel to the third

stringer from the bottom as shown in the photo.

T-34B Fact:

When the Navy evaluated the T-34,

they selected it as the best trainer available. They

could not just adopt the Air Force version,

however, as this would require them to share the

R&D costs. They made enough changes to the

aircraft that it could be classified as a “new”

model, the T-34B. While the changes were minor,

they did have an affect on the way the aircraft

handled. The dihedral of the wing was increased

by one degree and a spring system was added to

increase elevator stick forces.

-41-

Summary of Contents for T-34B MENTOR

Page 7: ...7 DIE CUT PATTERNS...