(not a felt-tip pen) to trace the outline of the landing

gear onto the rails so you know where

not

to apply

glue when you glue on the bottom sheeting. Later,

the sheeting over this area will be removed to

accommodate the landing gear mounts.

❏

14. Cut holes and slots in the W1’s on the ends of

the center section to match the holes for the servo

leads and retract air lines in the W2’s of the outer

panels. Cut the holes slightly oversize just in case

they don’t align perfectly.

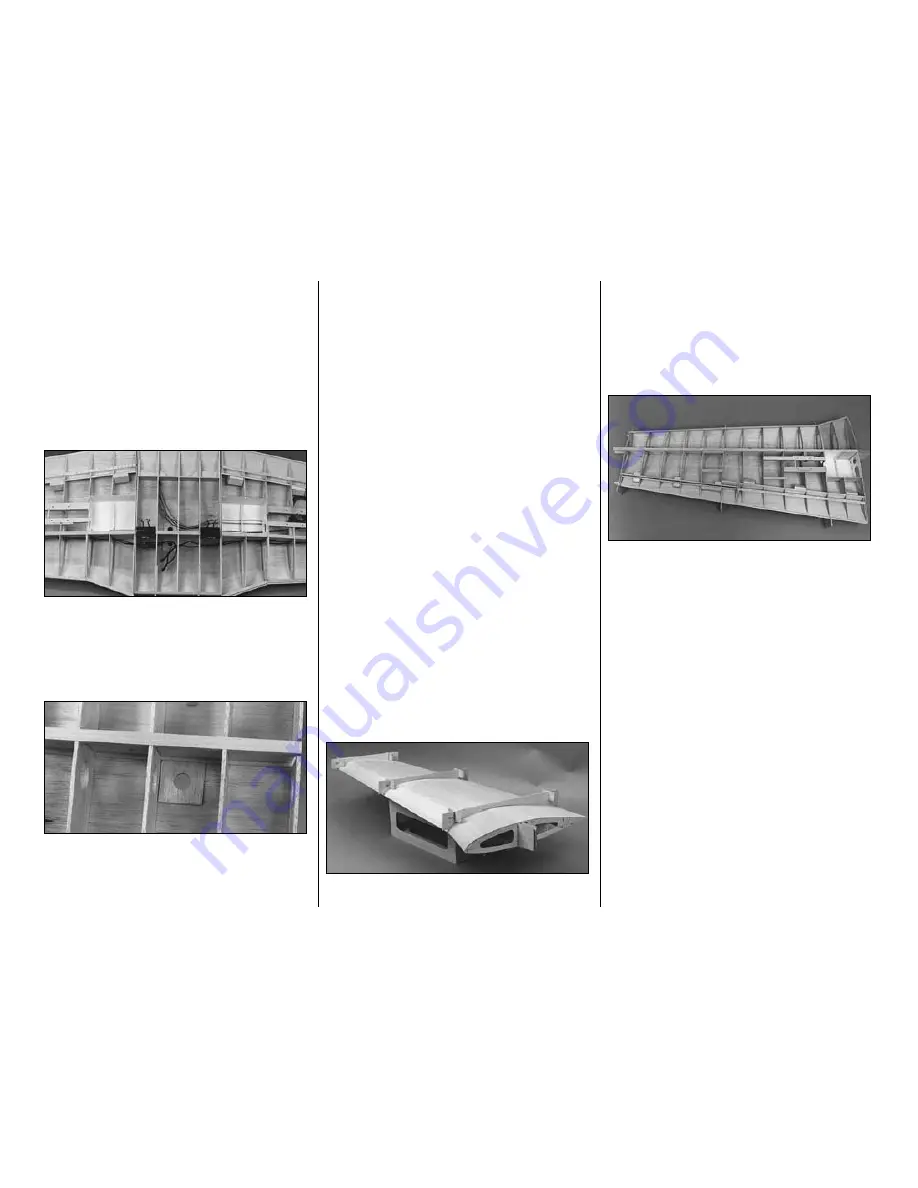

We’ve temporarily joined the wing panels and

installed the air lines and servo leads in the right

wing panel to mock-up the installation to give you an

idea of how to route them later. If you wish, you could

test your installation now to make sure your setup

will work.

❏

15. Glue a piece of leftover 3/32” [3.2mm] balsa to

the center section sheeting aft of the spar (note the

grain direction). Cut a 3/4” [19mm] hole through the

sheeting at this location for the servo cords and air

lines to exit the wing into the fuse.

❏

16. Separate the wing panels and remove the

servo cords and air lines but leave the tip light wires

in both outer wing panels.

❏

17. Sand the bottom of the outer wing panels with a

bar sander and 150-grit sandpaper so the spars, landing

gear and servo rails blend to the shape of the ribs.

SHEET THE WING PANEL BOTTOMS

❏

1. If you have not already done so, make the

forward and aft bottom wing skins the same way you

made the top wing skins on page 18.

❏ ❏

2. Use a ballpoint pen to mark the top sheeting

over ribs W14, W9 and W4 at the leading and trailing

edges. Check all glue joints and reinforce as needed.

❏ ❏

3. Test fit the die-cut 1/8” [3.2mm] balsa

wing

cradles W14C, W9C

and

W4C

on the top of the

wing, aligning them with the marks you made. Sand

away any slivers or slight die-cutting irregularities

until the cradles match the contour of the wing.

❏ ❏

4. Glue the die-cut 1/8” [3.2mm] balsa

feet

to the

cradles. Apply one drop of thick or medium CA near the

front and rear of each cradle and tack glue them to the

top wing sheeting in their proper locations. You only

need enough glue to hold the cradles to the wing so

they won’t fall off when you turn it upside down.

❏ ❏

5. Place the wing on your workbench so it is

resting on the cradles. Fit the bottom sheeting to the

wing. Trim the

stoppers on the cradles so the trailing

edge of the bottom sheeting aligns with the trailing

edge of the top sheeting. Trim the front edge of the

sheeting so it

ends at the center of the spar (the

same way as the top sheeting).

❏ ❏

6. Glue the aft bottom skin to the wing. Use T-pins

or weights to hold the skin in place until the glue dries.

Do Not

glue the skin to the servo hatch rails or where

the retracts will be mounted.

Caution:

Do not add too

much weight because this may bow the wing.

❏ ❏

7. Test fit, trim, then glue the

forward outer

skin

to the wing panel. Just the same as the top

forward outer skin, the wood grain should be parallel

to the

leading edge

of the wing panel.

-28-

Summary of Contents for T-34B MENTOR

Page 7: ...7 DIE CUT PATTERNS...