MOUNT THE WING TO THE FUSE

Remember the wing? Go get it so you can mount it

to the fuse.

❏

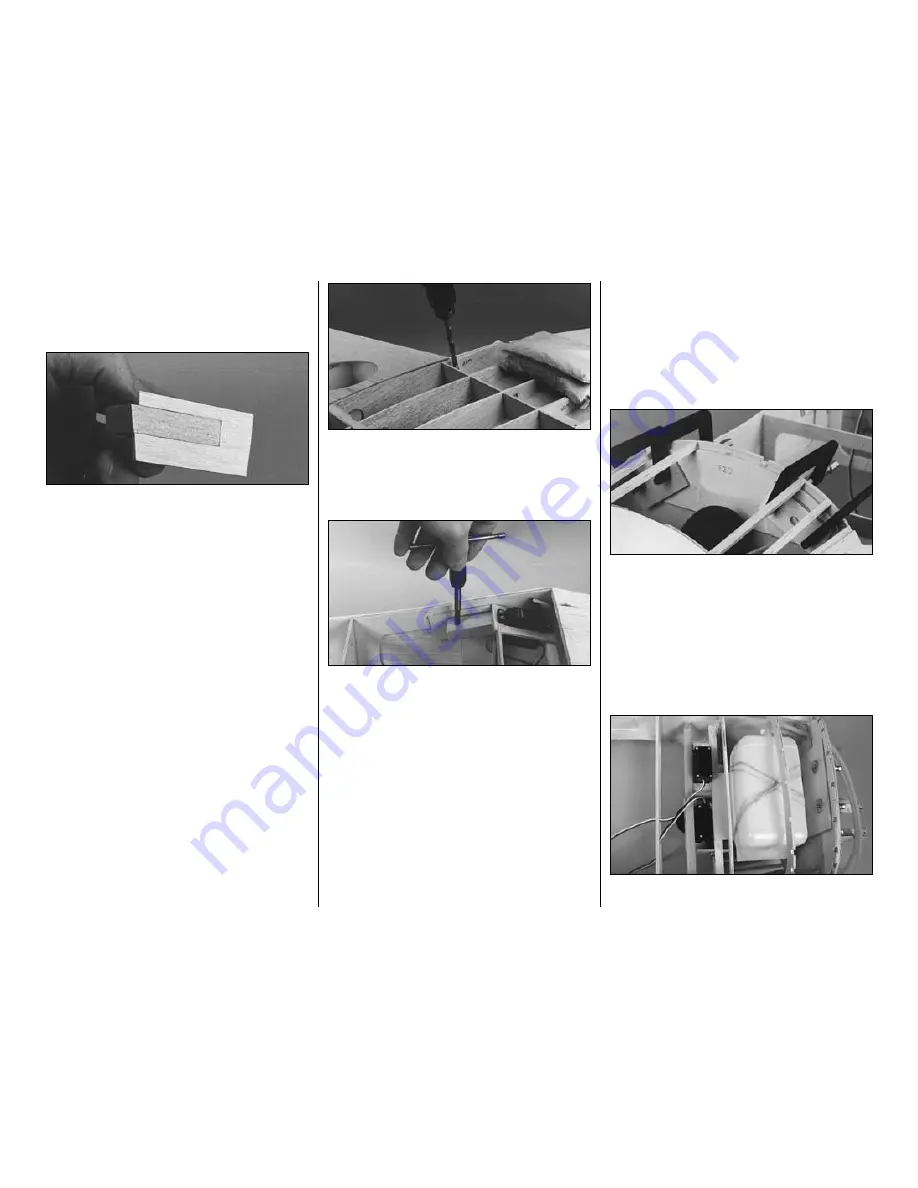

1. Bevel the end of both 1/2” x 1” x 2-1/4” [12.7 x

25.4 x 57.2mm] maple

wing bolt blocks

so they

match the angle of the die-cut 1/8” [3.2mm] plywood

wing bolt block holder

.

❏

2. Use 30-minute epoxy to glue the wing bolt

blocks and holders in the fuse where shown on the

plan. See the photo at step 8.

❏

3. Place the wing in the wing saddle on the fuse

with the dowels in the center section in the holes in

F2. Observe any

high spots in the saddle of the

balsa

fuse sides that prevent the wing from fitting.

Remove the wing and sand the high spots so the

wing matches the fuse as accurately as possible. Do

not sand the ply fuse side doublers. Also check that

the stab and wing are parallel.

❏

4. Remember the

pin and string method you used

to align the stab? Get your string out and stick a T-

pin in the center of the bottom, middle stringer just

ahead of the tail cone.

❏ ❏

5. Use the arrow on the tape to align the wing

with the fuse the same way you did the stab.

❏ ❏

6. Once you have the wing aligned, place weights

over the center section to keep it from shifting during

the next few steps. Keep your string handy so you can

recheck alignment as you proceed.

❏ ❏

7. Drill through

only one

wing bolt plate, the top

sheeting and the wing bolt block on one side of the

wing with a #7 drill. Keep the drill bit perpendicular to

the wing bolt plate as you drill so the head of the

wing bolt will rest flat.

❏ ❏

8. Remove the wing and tap threads into the

wing bolt block with a 1/4-20 tap. Enlarge the hole in

the wing bolt plate and the top sheeting with a round

file or a 17/64” [6.8mm] drill. Replace the wing on the

fuselage and bolt it down with the one 1/4” - 20 nylon

wing bolt.

❏

9.

Remount the #7 drill bit in your drill

. Repeat

steps 5, 6, 7 and 8.

❏

10. Bolt the wing to your fuselage and leave the

wing bolts barely snug. Realign the wing.

❏

11. Drill 1/4” [6.4mm] holes through the 1/8” x 1” x

2” [3.2 x 25.4 x 50.8mm] plywood

wing dowel

plates

.

Slightly

enlarge the holes with a round file or

a piece of sandpaper wrapped around something

round such as a pen or a piece of brass tube. This

will allow you to plug the wing into the fuselage

without too much resistance.

❏

12. Spread a thin film of 30-minute epoxy on one side

of both wing dowel plates and fit them over the dowels

protruding through former F2D inside the fuse.

Accurately mark the location of the plates on F2D.

❏

13. Remove the wing. Clamp the wing dowel

plates to F2D with C-clamps. Wipe excess epoxy

from the holes if any is present.

SHEET THE FORWARD DECK

The next several steps will be easier if you remove the

engine, engine mount and nose gear from the model.

Use this photo for the next three steps.

❏

1. Assemble your fuel tank. Position the tank floor

and the tank in the fuselage and determine where to

-50-

Summary of Contents for T-34B MENTOR

Page 7: ...7 DIE CUT PATTERNS...