❏

8. Return to step 1 and glue another side sheet to

the left fuse side the same way.

❏

9. Add pieces of leftover 3/32” [2.4mm] balsa to

extend the side sheets to the end of the fuselage.

See the photo at step 11.

❏

10. Remove the T-pins and lift the fuselage from

your building board. Reinforce glue joints you

couldn’t reach earlier or those that don’t look strong.

❏

11. Trim, then sand the fuselage side sheeting and

stringers that extend aft of former F11 so they are flush.

MOUNT THE STAB AND FIN

Note:

Build accurately during the next few steps. The

stab saddle and the aft formers align the stab and

set the incidence, which will greatly affect the way

your model flies.

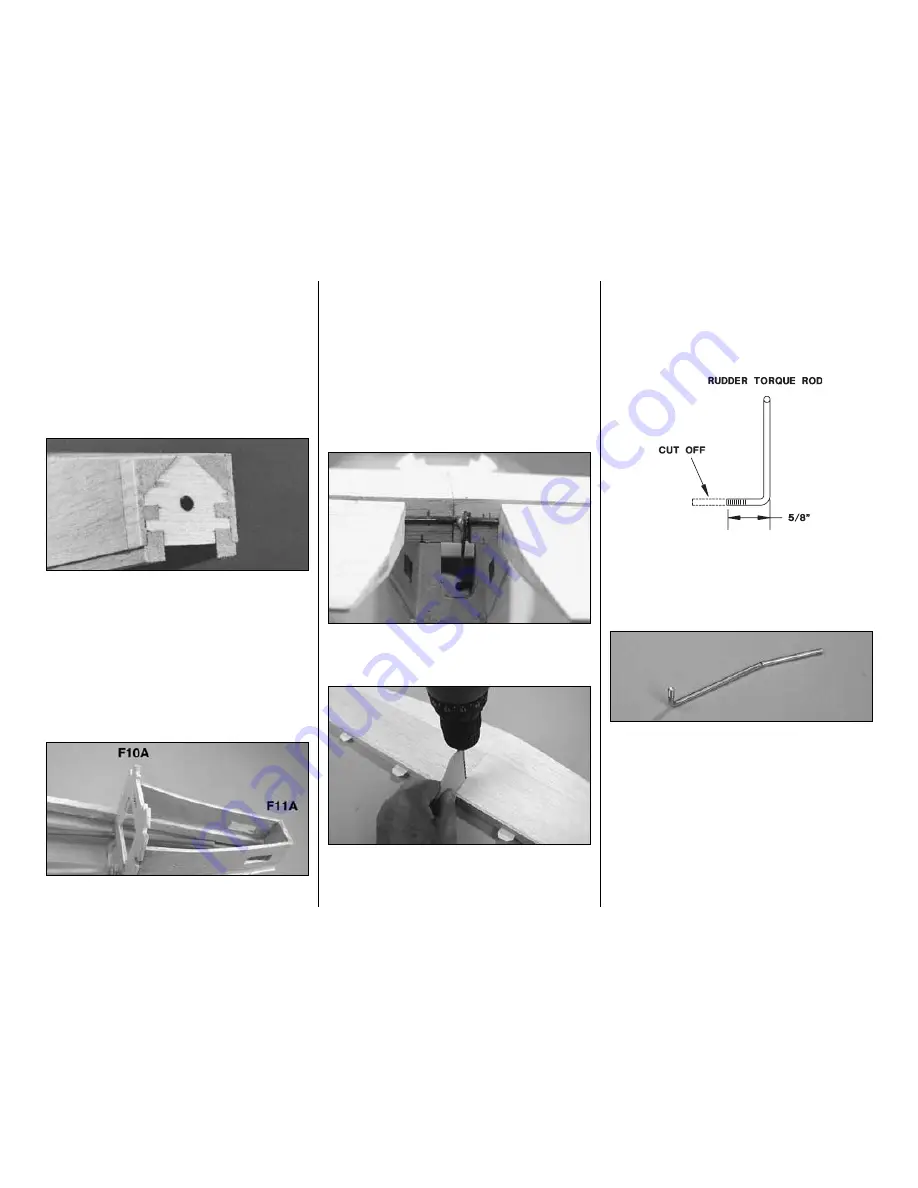

Use this photo for the next three steps.

❏

1. Glue the die-cut 1/8” [3.2mm] balsa

aft upper

former F11A

to former F11.

❏

2. Securely glue the die-cut 1/8” [3.2mm] plywood

stab saddles

to the top of the main fuse side

stringer and F11A.

❏

3. Glue the die-cut 1/8” [3.2mm] plywood

upper

former F10A

to the top of former F10. Glue the front

of the stab saddles to F10A.

❏

4. Use a bar sander with 80-grit sandpaper to sand

the

front

of the stab so the

TE will align with F11A when

it is placed on the stab saddle.

❏

5. Use a hobby knife or a Multi-Pro

™

with a

sanding drum to cut F11A to clear the horn on the

elevator joiner wire and the rudder torque rod.

❏

6. Mark the

center

of the stab 1-1/8” [28.6mm]

from the TE. Drill a 1/8” [3.2mm] hole through the

center of the stab at the mark. Use the die-cut 1/8”

[3.2mm] ply

90 degree gauge

as a guide to keep the

drill straight.

Hint:

A 6” [152mm] piece of 1/8”

[3.2mm] brass tube sharpened at one end cuts a

clean hole.

Note

: You must make sure you are drilling

in the center of the stab as you are drilling into the two

center 3/32” [2.4mm] ribs. Clean away any glue in the

joint so that the drill will get a clean start into the hole.

❏

7. Cut the threaded end of the

rudder torque rod

so the threads extend 5/8” [15.9mm] as in the sketch.

Tap threads in the nylon

swivel horn

with a 6-32 tap.

Thread it onto the rudder torque rod until it is even

with the end.

❏

8. The rudder torque rod must be bent 90 degrees

after

it is inserted through the stab. Make a mark on

the torque rod 2-1/2” [63.5mm] from the threaded

end of the rod. Place the torque rod on the side view

of the fuselage plan to confirm the mark is in the

correct place. Notice in the above photo that we have

made a

slight bend in the torque rod. This will help

insure that the 90 degree bend is made in the proper

direction in the next step. Also, notice the orientation

of the threaded end of the torque rod.

Caution:

Once

installed in the stab, the threaded end of the rod

must point to the left side and the 90 degree bend

must face aft into the rudder.

-38-

Summary of Contents for T-34B MENTOR

Page 7: ...7 DIE CUT PATTERNS...