❏

19. After the glue has thoroughly dried, remove all

the T-pins you can reach.

Carefully

lift the stab (with

the elevators) from your building board. Trim the jig

tabs from the ribs and take out the rest of the T-pins.

❏

20. Use a razor plane or a #11 blade to trim the

bottom

of the LE so it is the same size as the front

of the ribs and matches the airfoil shape.

❏

21. Sand the bottoms of the ribs, leading edges,

stab spars, elevator spars and the TE brace so they

smoothly blend.

❏

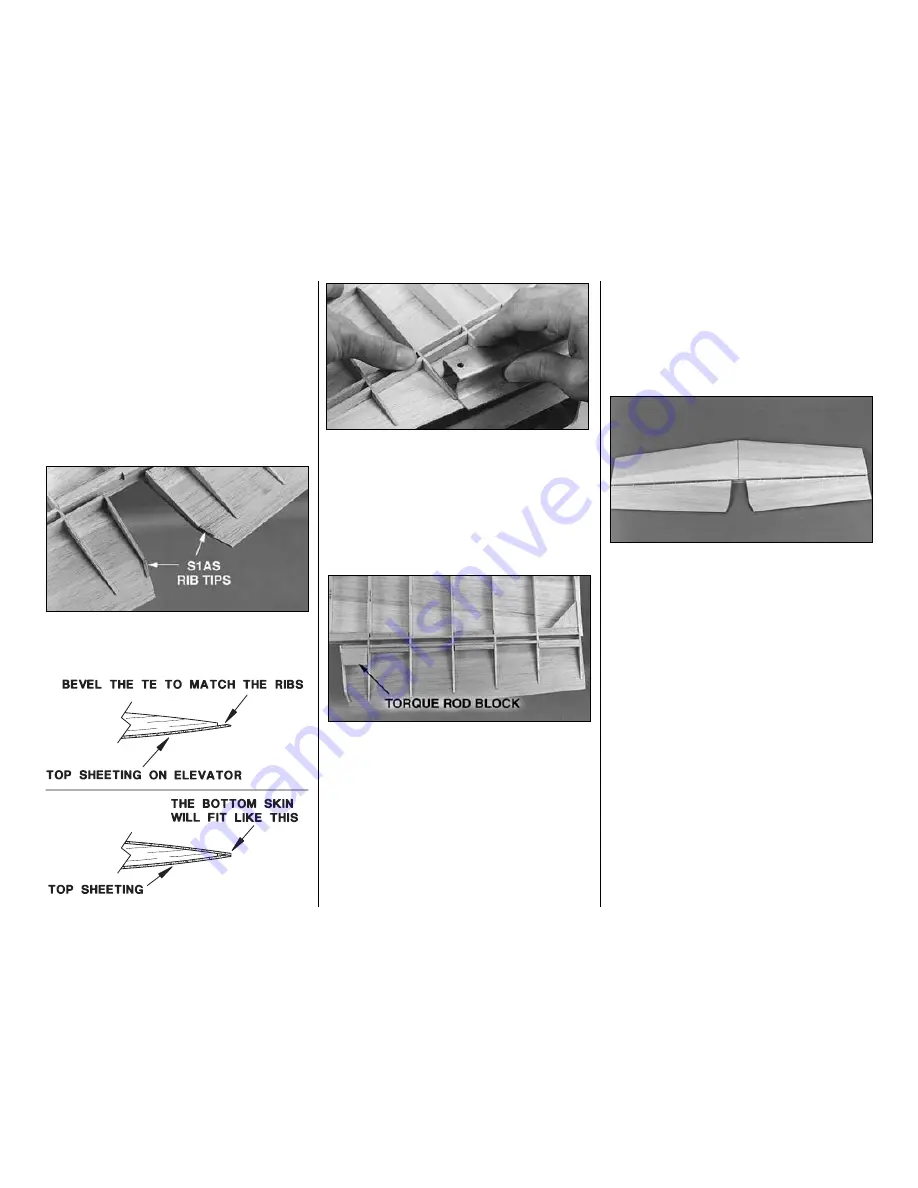

22. Glue the little tips you cut off the end of the

S1AS ribs to the sheeting and S1AS.

❏

23. Use a bar sander and 150-grit sandpaper to

bevel the trailing edge of the top elevator skin so it will

accommodate the bottom skin. While you sand, apply

pressure only to the sheeting and use the ribs to set

your sander at the correct angle. Do not bevel the

trailing edge to a

sharp edge but leave about 1/32”

[0.8mm]

squared off.

Hint:

Support the TE with the

edge of your workbench or a platform while you sand.

❏

24. Glue four die-cut 1/8” [3.2mm] balsa

elevator

torque rod blocks

between both sets of ribs S1AS

and S2S.

❏

25. Cut twelve 1-7/8” [47.6mm] long

hinge blocks

from the 1/4” x 3/8” x 36” [6.4 x 9.5 x 914mm] balsa

stick. Glue them evenly spaced vertically to the stab

TE spar and the elevator LE spar where shown on

the plan. Glue the die-cut 1/8” [3.2mm] balsa

stab

gusset

to the hinge block and rib S7S as shown on

the plan. Position the gusset so it is even with the

bottom of the hinge block so you do not break it

when you cut the hinge slot.

❏

26. Trim the elevator torque rod blocks and any

protruding hinge blocks so they are even with the

bottoms of the ribs.

❏

27. Reinforce any glue joints that do not look strong.

Use this photo for the next two steps.

❏

28. Glue the elevator skins to the bottom of the

elevators so the trailing edges align.

Optional:

Use the die-cut 1/8” [3.2mm] balsa

stab

cradles S2T

and

S7T

to hold the stab flat on your

workbench while you glue the bottom skins on. Use

the stab cradles the same as the wing cradles shown

in steps 1-5 on page 28.

❏

29. Glue the stab skins to the bottom of the stab.

If you have not used any accelerator on the stab you

may glue the skins on with thick or medium CA.

Otherwise, use aliphatic resin. Work over a flat work

surface and be careful not to add any twist into the

stab as you press the skins to the stab frame.

❏

30. After the glue dries, use a bar sander with 150-

grit sandpaper to sand the sheeting even with the

ends of the stab and elevators.

❏

31. Cut the ribs and separate the elevators from

the stab. Sand the excess sheeting and rib stubs

from the TE of the stab and the LE of the elevator.

Sand the elevator sheeting even with rib S1AS.

-13-

Summary of Contents for T-34B MENTOR

Page 7: ...7 DIE CUT PATTERNS...