Section 3

ThermoFlex 3-9

Thermo Scientific

Plumbing

Requirements

Ensure that all shipping plugs are removed before installation.

Never connect the process fluid lines to your facility water supply or

any pressurized liquid source.

To prevent damage to the chiller's plate exchanger, centrifugal pumps

require a 4.0 gpm (15.1 lpm) minimum flow rate.

P 1 and P 2 pumps are capable of producing 185 psig. Ensure your

plumbing is rated to withstand this pressure at your operating

temperature. An external pressure relief valve is available, see Section 5.

Note

Ensure your plumbing installation develops a back pressure to the

ThermoFlex greater than 3 PSIG. Lower pressure will shut down the chiller.

The process fluid connections are located on the rear of the chiller and are

labeled

(PRoCESS ouTLET) and

(

PRoCeSS InLeT

).

Process Fluid Connections (FNPT)

outlet

ThermoFlex900 - 10000

P 1 P 2 T 0 T 1 1/2" cast bronze

ThermoFlex3500 - 5000

P 3 P 4

3/4" cast bronze

1" wrought copper

ThermoFlex7500 - 24000 P 3 P 5 T 5

T9

Inlet - Same size as outlet

all connections stainless steel

Supplied Adapters

P 1 P 2 T 0 T 1 1/2" x 3/8'' barb polyethylene and 1/2" x 1/2" barb

nylon P 3 P 4

3/4" MPT x 1/2" barb PVC

P 3 P 5 T 5 T 9

1" MPT x 1" barb PVC and 1" MPT x 3/4" barb PVC

CAUTION

CAUTION

CAUTION

1/4" Female NPT Riton Reservoir

Drain Plug

See Section 2 for the specific

locations on your chiller.

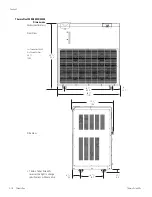

Figure 3-4

Typical Plumbing Connections (1 of 2)

DRAIN

Stainless steel outlet connection for chillers

with P 1/P 2 pumps and a flow transducer

Summary of Contents for ThermoFlex10000

Page 2: ......

Page 36: ...ThermoFlex900 5000 Thermo Scientific...

Page 42: ...DI SDS 4 0 gpm 15 1 lpm ThermoFlex900 5000 Thermo Scientific...

Page 79: ...517 2014 16 2014 ThemoFlex24000...

Page 100: ...Section 2 2 20 ThermoFlex Thermo Scientific...

Page 136: ...Section 4 4 14 ThermoFlex Thermo Scientific...

Page 168: ...Section 7 7 14 ThermoFlex Thermo Scientific...

Page 191: ...C 10 ThermoFlex Appendix C Thermo Scientific...

Page 208: ......

Page 209: ......