Texmate, Inc. Tel. (760) 598-9899 • www.texmate.com

Page 14

Apr-21-2016 DI_602A 320 DS (NZ313)_April 2016

[CAL] - Calibration Modes for Input and Output continued

[CAL] - Calibration Modes for Input and Output continued

Related Calibration Functions

The following functions are also configured in the calibration

mode. See

Advanced Calibration and On Demand Mode

Supplement (NZ203)

for further calibration details.

Serial Communications Properties

Selecting [CAL][20X] enters the Serial Communications

Properties Mode.

This mode allows you to configure the serial communications

output module baud rate, parity, time delay, and address set-

tings.

See the

calibration modes

diagram on Page 13 showing a

breakdown of 1st, 2nd, and 3rd digits.

Also see the Serial Communications Module Supplement

(NZ202) for further details on the serial communications module.

Set Auto Zero Maintenance

Selecting [CAL][21X] enters the Set Auto Zero Maintenance

Mode.

This mode allows you to configure auto zero maintenance set-

tings for weighing applications applied to the channel selected

in the 3rd digit.

See the

calibration modes

diagram on Page 13 showing a

breakdown of 1st, 2nd, and 3rd digits.

Set Averaging Samples & Averaging Window

Selecting [CAL][22X] enters the Set Averaging Samples and

Averaging Windows Mode.

This mode allows you to configure the number of input signal

samples to average over, and the size of the averaging window

in display counts applied to the channel selected in the 3rd digit.

Selecting [CAL][22X] enters the Set Averaging Samples and

Averaging Windows Mode. When in this mode, the [AV_S]

menu allows you to select the number of input signal samples

to average over. After setting the number of samples, moving

to the [AV_W] menu allows you to configure the size of the

averaging window in displayed counts.

The meter averages the input samples over the selected num-

ber of input samples (selected in the [AV_S] menu). This carries

on in a continual process provided the input signal stays within

the averaging window (set in the [AV_W] menu). If the sample

moves out of the averaging window, the meter responds quick-

ly to the change by displaying the non-averaged signal value.

When the signal stabilizes, a new averaging window is estab-

lished and averaging resumes.

You can program the number of samples you want to average

the input signal over from 1 to 255 samples. The averaging

window can be set to between 1 and 65535 counts.

See the

calibration modes

diagram on Page 13 showing a

breakdown of 1st, 2nd, and 3rd digits.

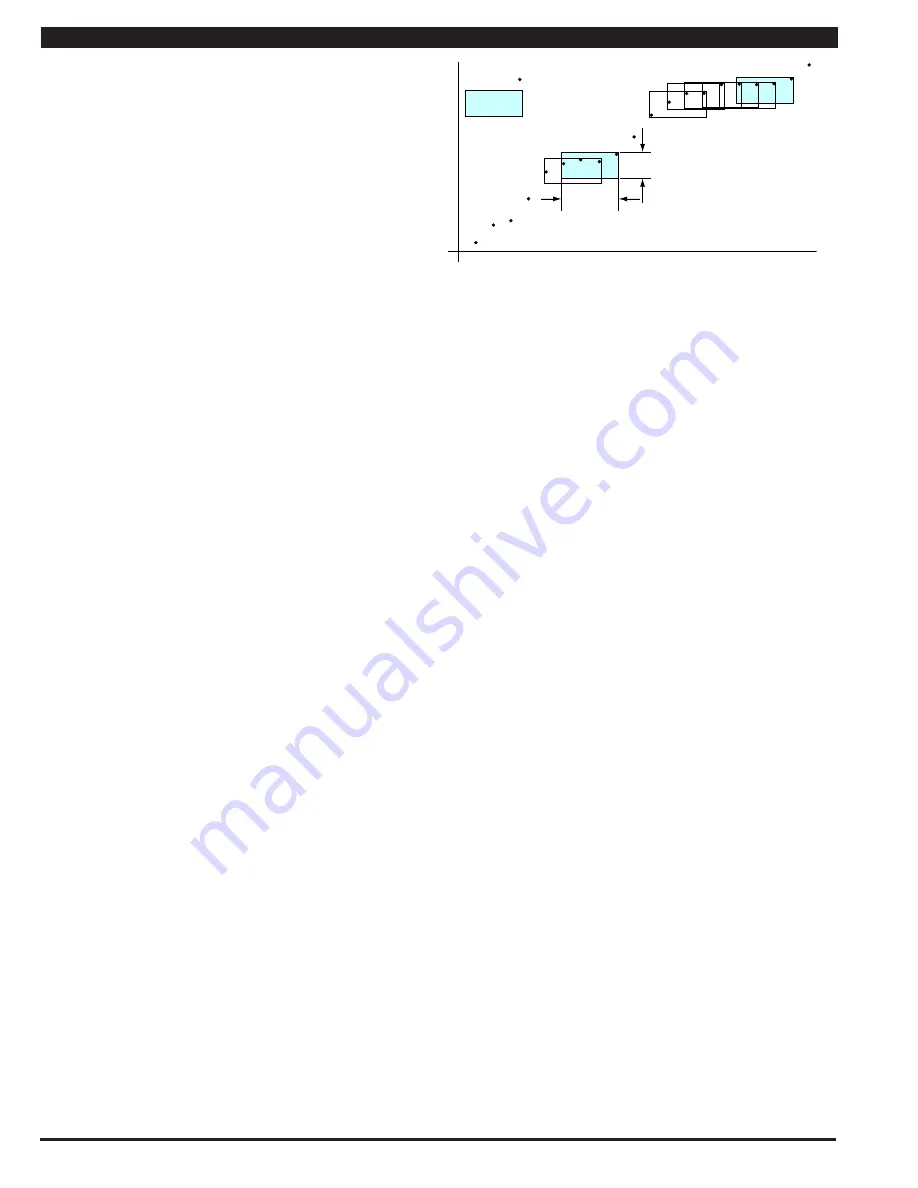

See Input Signal Sampling Showing Averaging Window dia-

gram opposite.

Example Procedure

The example procedure on Page 16 shows how to configure

channel 1 (CH1) with an averaging sample rate of 10 counts

and an averaging window of 1000 counts.

Totalizer Settings

Selecting [CAL][23X] enters the Totalizer Settings Mode.

This mode allows you to configure the settings for the totalizer

selected in the 3rd digit. An input value of 10000 counts is

applied to a selectable time period to produce the required

total value.

The cutoff is a programmable limit below which the input is not

totalized.

See the

calibration modes

diagram on Page 13 showing a

breakdown of 1st, 2nd, and 3rd digits.

Also see the Totalizing and Batching Supplement (NZ208) for

further details on K factor and totalizer cutoff parameters.

Setup 32-point Linearization Tables

Selecting [CAL][24X] enters the Setup 32-point Linearization

Tables Mode.

This mode allows you to set up the linearization table or tables

using the manual or auto setup modes. The table or tables can

then be selected to linearize the signals on channels 1 to 4.

See

Linearization Table Notes

on Page 28 for a description of

memory related issues with linearization.

See the

calibration modes

diagram on Page 13 showing a

breakdown of 1st, 2nd, and 3rd digits.

Also see the Linearizing Supplement (NZ207) for further details

on linearization table setup and use.

Scale Analog Output

Selecting [CAL][25X] enters the Scale Analog Output Mode.

This mode allows you to calibrate and scale the analog output

signal. Before calibrating the analog output in the calibration

mode, the data source for the analog output must be configured

in Code 1.

See the

calibration modes

diagram on Page 13 showing a

breakdown of 1st, 2nd, and 3rd digits.

Also see the Analog Output Module Supplement (NZ200) for

further details on the analog output module.

Also see Configure Data Source Procedure on Page 19 for an

example of setting the analog output data source.

Calibration Mode Procedures Supplement

The

Advanced

Calibration and On Demand Mode Procedures

Supplement

(NZ203) describes in detail all Tiger 320 Series

meter related calibration procedures configured in the calibra-

tion mode.

Sampling

Input Signal in Counts

= Samples

= Averaging Window

Averaging Window

in Displayed Counts

Number of

Samples

Input Signal Sampling Showing Averaging Window