7 MAINTENANCE

ATTENTION: for repairs or replacement of parts for maintenance, the ‘CE’ mark is guaranteed

only if original spare parts provided by the manufacturer are used.

Although the UC199 key-cutting machine does not require special maintenance, it is advisable to check and, if

necessary, replace the parts subject to wear and electric/electronic parts (fuses, circuit boards, etc.) in the event

of faulty operation.

ATTENTION: for normal servicing of the burnished mechanical parts, we recommend using

lubricants or protective oil, e.g. WD40 or similar. Do not contaminate the electronic parts

with the oil.

Replacement is simple and can be carried out by the operator consulting the instructions.

Before starting any type of maintenance (controls or replacements), read the instructions below:

•

never carry out maintenance with the machine switched on

•

always remove the main power supply cable

•

strictly follow all the instructions in the manual

•

use original spare parts (see Spare Parts sheet provided).

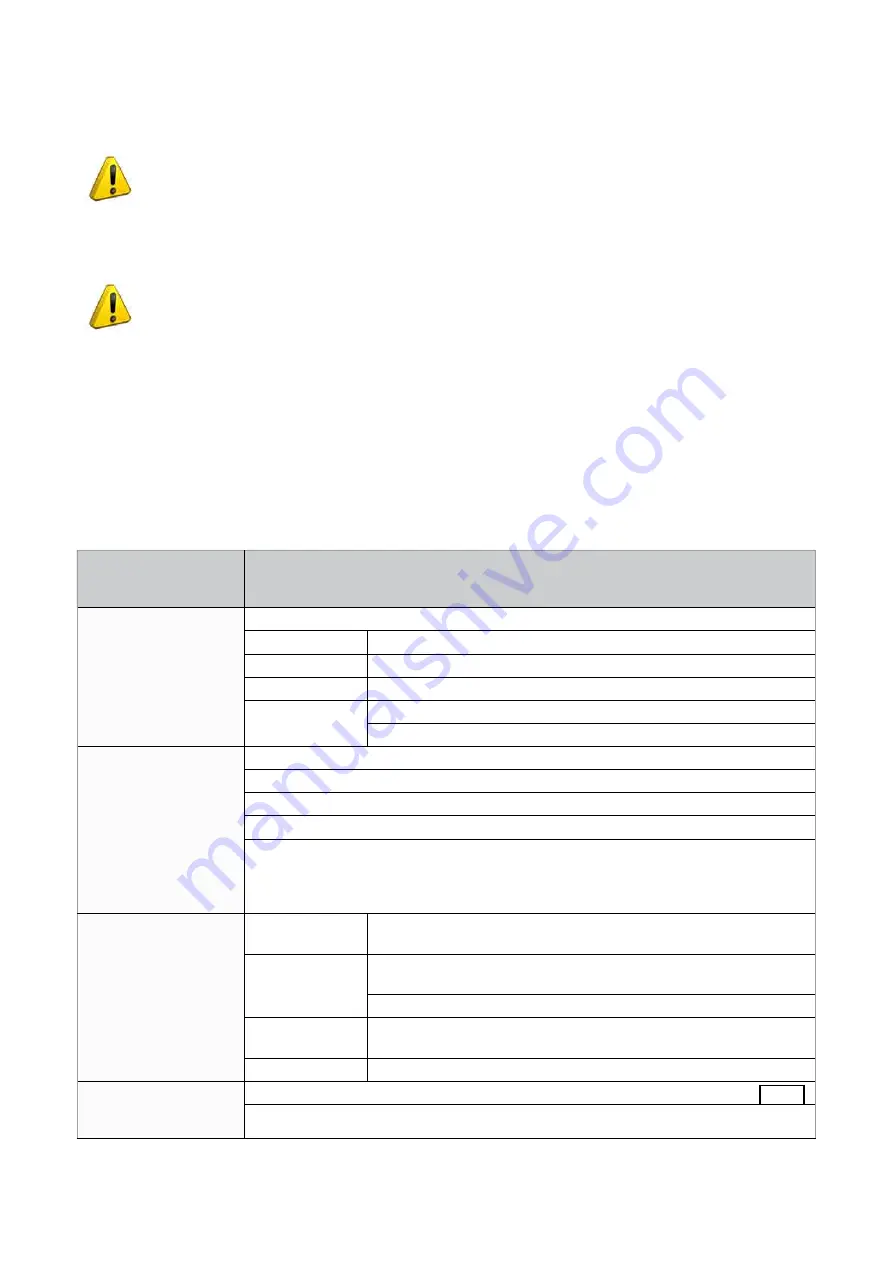

7.1 TROUBLE SHOOTING

FAULT

PROBABLE CAUSE

Machine is on, with no

message on its display:

check to see if the back fan is working:

Not working

a) emergency button activated

b) general fuses in the power socket are faulty

Working

a) fuse F3 on electronic control board is faulty

b) connection wire between display and electronic circuit board loose

c) defective display

cutter motor not working: a) the closed protective shield is not making proper contact with the safety microswitch

b) the F1 fuse on the electronic control board is faulty

c) motor wire not properly attached to the connector

d) defective electronic control board

e) motor cut-off

WARNING: this may derive from inappropriate or heavy use of the key-cutting machine

or a fault with the motor itself. DO NOT USE THE MACHINE and call Technical Silca

Dept. to determing the cause of activation of the cut-off

X, Y and B axes motors

are not working

None of the mo-

tors working:

a) fuse F2 on the electronic control board faulty

b) the wiring between the transformer and electronic control board is

loose or the connector is not seeded properly

c) defective electronic control board

Only one motor is

not working:

a) the connection wires between the motor and the electronic control

board are loose or the connector is not seeded properly

b) defective electronic control board

Protective shield is

closed but the display

reads “close shield”

a) the closed protective shield is not making proper contact with the microswitch (Fig. 72)

b) the F4 fuse on the electronic control board is faulty

Operating Manual

UC199

Copyright Silca 2012

70

Summary of Contents for UC 199

Page 81: ...Fig 82 Fig 83 Operating Manual UC199 Copyright Silca 2012 77...

Page 86: ...Fig 93 Operating Manual UC199 Copyright Silca 2012 82...

Page 94: ...Operating Manual UC199 Copyright Silca 2012 90...

Page 96: ...ELECTRICAL DIAGRAMS Operating Manual UC199 Copyright Silca 2012 92...

Page 97: ...Operating Manual UC199 Copyright Silca 2012 93...

Page 98: ...Operating Manual UC199 Copyright Silca 2012 94...

Page 99: ...Operating Manual UC199 Copyright Silca 2012 95...

Page 100: ...Operating Manual UC199 Copyright Silca 2012 96...

Page 101: ...Terminal board connection Operating Manual UC199 Copyright Silca 2012 97...

Page 102: ...UC199 KEY CUTTING MACHINE OPTIONAL LOADER UNIT Operating Manual UC199 Copyright Silca 2012 98...

Page 103: ...Operating Manual UC199 Copyright Silca 2012 99...