7.Detailed Descriptions

256

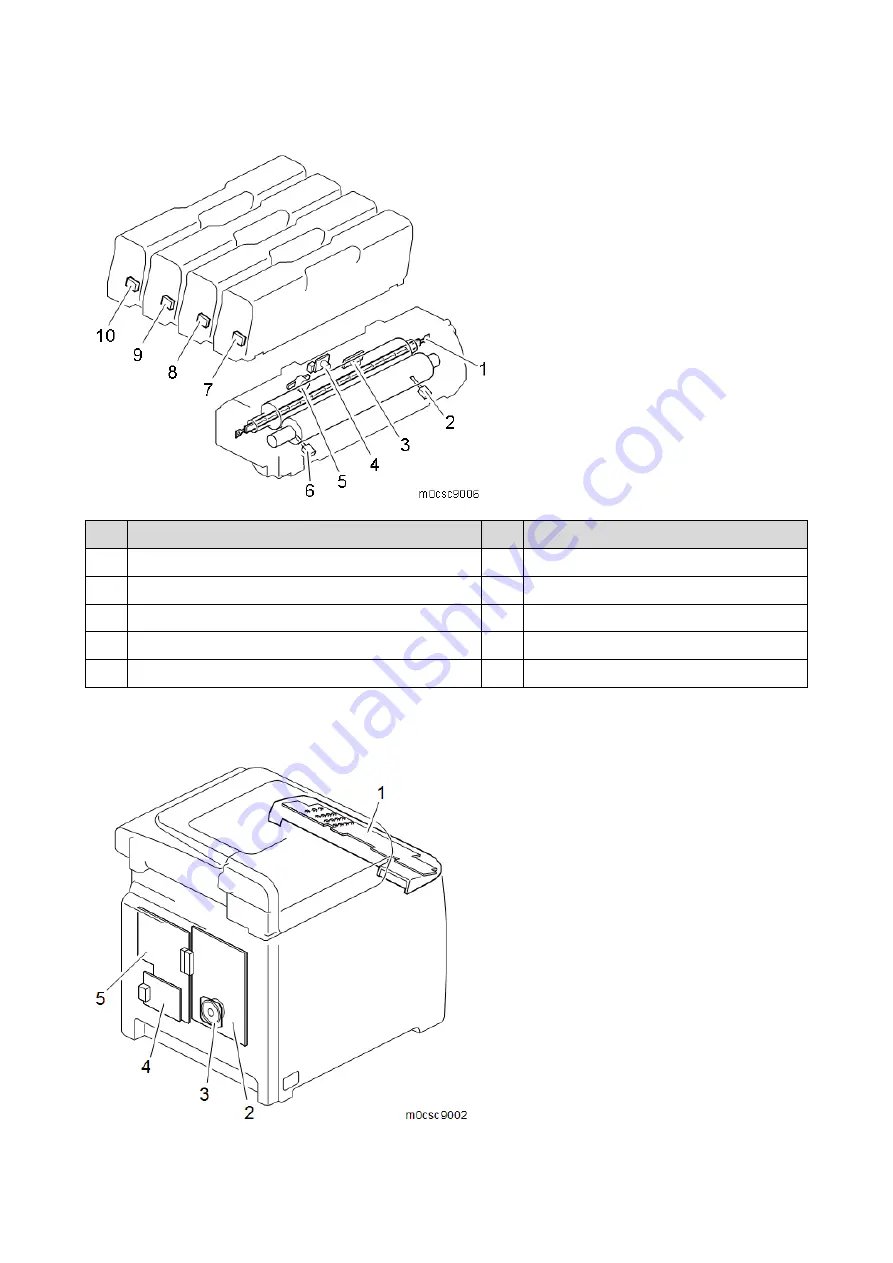

Fusing Unit, ID Chip

No.

Name

No.

Name

1

Fusing lamp (H1)

6

Pressure roller thermistor (end) (TH4)

2

Pressure roller thermistor (center) (TH3)

7

ID chip (K)

3

Fusing NC sensor (S1)

8

ID chip (Y)

4

Fusing thermopile (TH2) *At main machine side

9

ID chip (M)

5

Fusing thermostat (TH1)

10

ID chip (C)

Boards

Summary of Contents for M C250FW

Page 2: ......

Page 8: ......

Page 12: ......

Page 34: ...3 Preventive Maintenance 22 to remove any remaining moisture ...

Page 45: ...4 Replacement and Adjustment 33 6 Release the belt A and then remove the front cover unit B ...

Page 103: ...4 Replacement and Adjustment 91 MF model 11 Remove the fusing transport drive unit A ...

Page 112: ...4 Replacement and Adjustment 100 MF model 8 Remove the belt cover A ...

Page 183: ...5 System Maintenance 171 8 Press OK on the screen or press on the number keys to exit ...

Page 188: ...5 System Maintenance 176 Special Sender List Configuration Page Printer model ...

Page 189: ...5 System Maintenance 177 MF model ...

Page 260: ...6 Troubleshooting 248 Flowchart ...

Page 271: ...7 Detailed Descriptions 259 ...

Page 297: ...7 Detailed Descriptions 285 Boards Block Diagram Printer Model ...

Page 301: ......