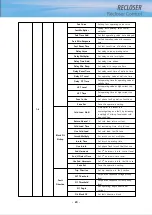

[ S e t t i n g

M E N U ]

→

1 . F u n c G r o u p 1

2 . F u n c G r o u p 2

3 . F u n c G r o u p 3

4 . F u n c

G r o u p 4

5 . S e l e c t

G r o u p

[ F u n c

S e t t i n g ]

→

1 . P h a s e

F a u l t

2 . G r o u n d

d

F a u l t

3 . S E F

F a u l t

4 . T r i p

&

R e c l o s e

5 . A u x i l i a r y

F u n c

- 38 -

<Figure 5-7> Setting Menu- Func Group

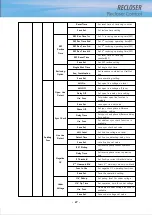

5.2.3. Phase Fault

In order to detect phase fault, setting items and ranges are like below.

<Table 5-1> Detecting phase fault

Category

Item

Range

Default

Step

Unit

Explanation

Op Level

& Time

Pickup Level

10~2000

400

1

A

Set operation level

Fast Curve

1~50

A Curve

Set fast curve

Fast Multiplier

0.05~2

1.00

0.01

Set a multiplier of fast operating

curve.

Fast Time Add

0.00~1.00

0.00

0.01

sec

Set operating delayed time under fast

curve condition

Fast Min

Response

0.00~1.00

0.00

0.01

sec

Set min. operating response time

under fast curve condition

Fast Reset Time

0.00~1.00

0.00

0.01

sec

Set fast reset time of definite time

Delay Curve

1~50

B Curve

Set delay curve

Delay Multiplier

0.05~2

1.00

0.01

Set a multiplier of delay operating

curve.

Delay Time Add

0.00~1.00

0.00

0.01

sec

Set operating delayed time under

delay curve condition

Delay Min Resp

0.00~1.00

0.00

0.01

sec

Set minimum operating response time

under delay curve condition

Delay Reset Time

0.00~1.00

0.00

0.01

sec

Set delay reset time of definite time

Delay DT Level

25~10000

OFF

1

A

Set operating value at delay DT level

Delay DT Time

0.01~2

2.00

0.01

sec

Set operating time at delay DT time

HCT Level

25~10000

OFF

1

A

Set operating value at high current

trip level

HCT Time

0.01~1

0.04

0.01

sec

Set operating time at high current

trip time

Func In Use

NO/YES

YES

Set phase fault operation functions

Block flt

Pickup

Cold Load Multi

1~10

2

1

A multiplier to prevent the

mis-recognizing as a fault by

increasing a multiply of pick-up level

under cold load condition.

Return Normal I

0~30

0.3

0.01

sec

Set the return current of restraining

operation against cold load

Cold Load Time

0~180

3

1

min

Set restraining time of cold load

Use Cold Load

NO/YES

NO

Set cold load Use/Not use

Inrush Multiply

1~10

2

1

A multiplier to prevent the mis-

recognizing as a fault by increasing a

multiple of pick-up level under inrush

condition

Inrush Time

0~30S

0.02

0.01

sec

Set restraining time of Inrush

Use Inrush

NO/YES

NO

Set inrush Use/Not use

2nd Harmonic

1-50

20

1

%

A level of regarding 2

nd

harmonic as

inrush

Use 2nd Harmonic

0.02~1

0.02

0.01

sec

Set 2

nd

harmonics Use/Not use

Summary of Contents for RECLOSER

Page 1: ...User Manual Document Version 1 5 Feb 28 2019 http powersys kr http www powersys kr...

Page 14: ...8 3 5 Mechanical Performance and Size Weight 3 5 kg FRONT VIEW Figure 3 1 Front View...

Page 15: ...9 SIDE VIEW 343 00 310 00 91 00 Figure 3 2 Side View...

Page 16: ...10 TOP VIEW 84 0 260 0 225 0 1 0 0t Figure 3 3 Top View...

Page 17: ...11 REAR VIEW 180 0 120 0 Figure 3 4 Rear View...

Page 22: ...16 Controller PCB 215 00 103 90 121 10 112 50 112 50 235 00 205 00 Figure 3 8 Controller PCB...

Page 69: ...63...

Page 71: ...65 Example configuration file...

Page 73: ...67 2 TC Curve 1 4 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting 1 2 3 4...

Page 74: ...68 3 TC Curve 5 8 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting 5 6 7 8...

Page 77: ...71 6 TC Curve A D 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting A B C D...

Page 78: ...72 7 TC Curve E M 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting E K L M...

Page 79: ...73 8 TC Curve N T 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting N P R T...

Page 80: ...74 9 TC Curve V Z 100 101 10 1 100 101 102 Time sec Current In Multiplies of Setting V W Y Z...