INF-15

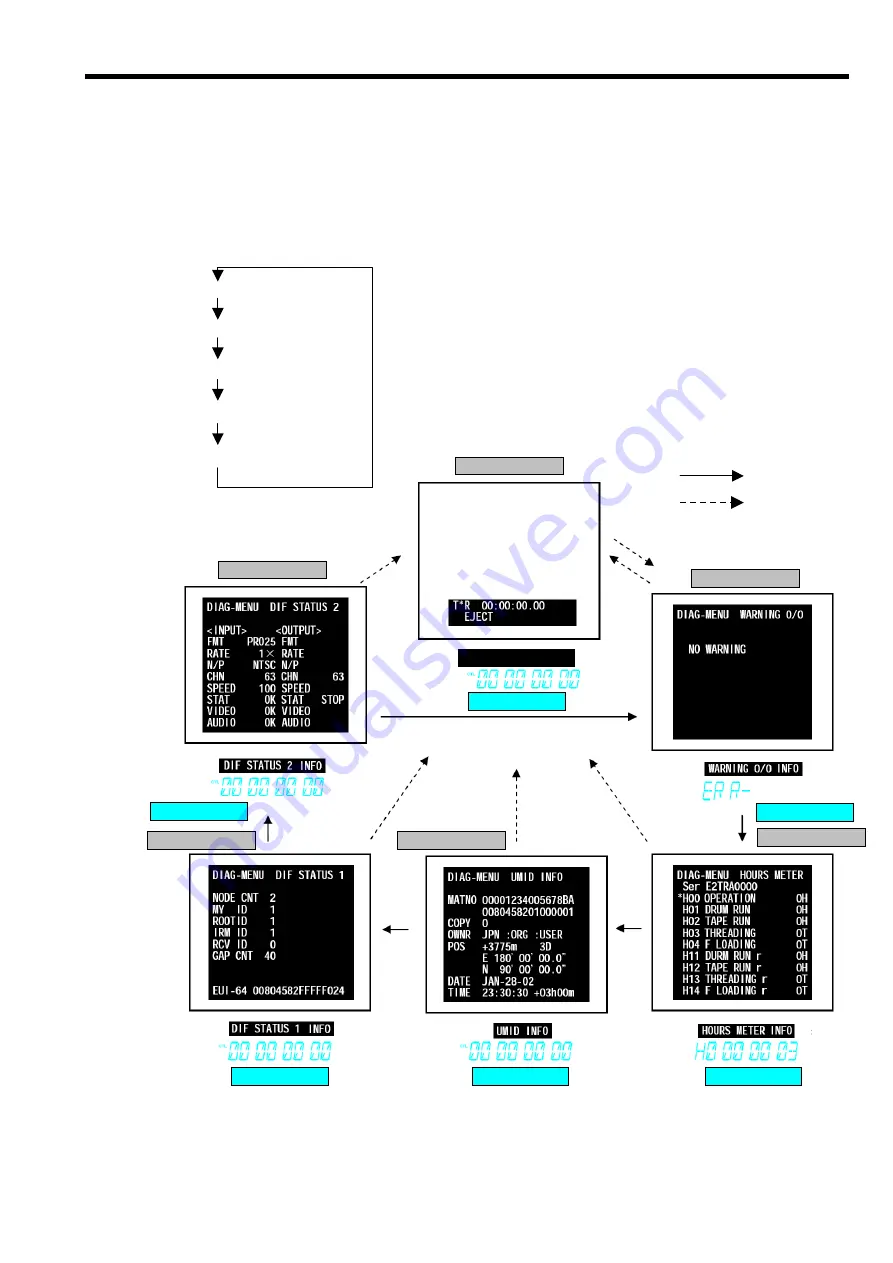

9. DIAG MENU DISPLAY

The DIAG-MENU is the menu for investigating the status of the VTR, and it has the indicated information.

• Warning display (WARNING information)

• Hour meter display (HOUR METER information)

• UMID display (UMID information)

• DIF status display (DIF STATUS 1 and 2 information)

1.

Press

the

“DIAG”

button so that the above information is displays on the monitor and Front Display.

2.

Press

the

“SEARCH”

button in order to change the display as shown below.

3. The Diag Menu is closed by pressiing the

“DIAG”

button again.

Monitor Screen

Monitor Screen

Monitor Screen

Monitor Screen

Monitor Screen

Monitor Screen

Front Display

Front Display

Front Display

Front Display

Front Display

Front Display

NORMAL SCREEN

Note:

: SEARCH Button

: DIAG Button

HOUR METER SCREEN

WARNING O/O SCREEN

DIF STATUS 2 SCREEN

UMID INFO SCREEN

DIF STATUS 1 SCREEN

Summary of Contents for AJ-D93MC

Page 3: ... 3 ...

Page 4: ... 4 AJ D93MC ...

Page 5: ... 5 ...

Page 6: ... 6 AJ YA93P AJ YA94G ...

Page 8: ... 8 AJ SD93P E ...

Page 9: ... 9 ...

Page 10: ... 10 ...

Page 11: ... 11 AJ YA93P AJ YA94G ...

Page 12: ...FCD0409NTKK145E466E467 ...

Page 65: ...INF 52 14 ERROR MESSAGES ...

Page 66: ...INF 53 ...

Page 67: ...INF 54 ...

Page 68: ...INF 55 ...

Page 110: ...MECH 32 Figure 3 35 2 Confirm this value ...