MECH-40

5. MAJOR MECHANICAL PARTS REPLACEMENT &

ADJUSTMENT PROCEDURES

When mechanical parts are replaced, pay attention to

the following notes.

1. Always turn power off before replacing any parts.

2. If any adjustment is required after replacing parts,

perform the required adjustment.

3. Use proper tools and fixtures.

4. Be sure to clean the parts after replacement, and

also to replace the mechanical parts, following the

replacement procedure.

5-1. Cylinder Unit Replacement

(Removal)

1. Remove the T1 Guide and Cleaning Arm Unit.

(Please refer to item “5-2. Cleaning Arm Unit

Replacement”)

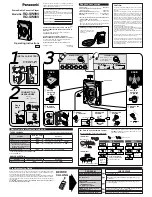

Figure 5-1-1

2. Unscrew the screw (B) which fixes the cable (B) as

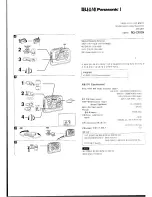

shown in Figure 5-1-2.

3. Remove the flexible cable which is connected to

P33 on the MECH I/F as shown in 5-1-1.

4. Unscrew the 3 screws which has spring from the

Cylinder Unit as shown as Figure 5-1-1, then

remove the Cylinder Unit without touching any

mechanical parts.

Figure 5-1-2

NOTE:

Don’t touch the cylinder by finger directly, when

removing the Cylinder Unit.

(Installation)

1. Install the new Cylinder Unit according to the

opposite procedures of removing.

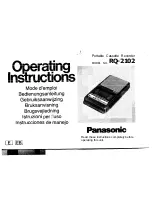

Figure 5-1-3

NOTE:

When installing the Cylinder Unit, the pin on Mech.

Chassis should match with holes of Cylinder Unit as

shown in Figure 5-1-3.

2. After installing the T1 Guide, T1 Guide Position

Adjustment should be performed.

(Please refer to item “5-2. Cleaning Arm Unit

Replacement” and “5-3. T1 Guide Position

Adjustment”)

Connectors (A)

(P33)

Screws (A)

Screws (C)

Screw (B)

T1 Guide

Cable (C)

Cable (B)

Cable (A)

Summary of Contents for AJ-D93MC

Page 3: ... 3 ...

Page 4: ... 4 AJ D93MC ...

Page 5: ... 5 ...

Page 6: ... 6 AJ YA93P AJ YA94G ...

Page 8: ... 8 AJ SD93P E ...

Page 9: ... 9 ...

Page 10: ... 10 ...

Page 11: ... 11 AJ YA93P AJ YA94G ...

Page 12: ...FCD0409NTKK145E466E467 ...

Page 65: ...INF 52 14 ERROR MESSAGES ...

Page 66: ...INF 53 ...

Page 67: ...INF 54 ...

Page 68: ...INF 55 ...

Page 110: ...MECH 32 Figure 3 35 2 Confirm this value ...