3

Introduction and Features

Section 1-1

Word Allocation

Data is exchanged between the CPU Unit and the Temperature Control Unit

through the PLC’s memory areas. A part of the CIO Area (the Special I/O Unit

Area) and part of the DM Area are reserved for the Special I/O Units.

The Temperature Control Unit requires 20 words in the CIO Area and 100

words in the DM Area. (The unit number set on the front of the Unit deter-

mines which words are actually allocated to the Unit.)

1-1-2

Features

Use ON/OFF Control or

PID Control with 2 or 4

Control Loops

The Temperature Control Unit can perform basic ON/OFF control as well as

PID control of two or four control loops. The PID control function has two

degrees of freedom and an autotuning function that can be used to autotune

the PID value.

Connect Temperature

Sensors Directly

Temperature sensors can be connected directly to the Temperature Control

Unit (two or four inputs). There are two models that support thermocouples

(R, S, K, J, T, B, and L thermocouples) and two models that support platinum

resistance thermometers.

500-ms Sampling Cycle

PID control is performed with a sampling cycle of 500 ms, regardless of the

CPU Unit’s cycle time.

Unrestricted CPU Unit

Cycle Time

There are no restrictions on the CPU Unit’s cycle time.

RUN/STOP Control from

CPU Unit

Commands can be sent from the CPU Unit to switch the Temperature Control

Unit’s PID control between RUN and STOP.

Independent Operation in

PROGRAM Mode

A switch on the front of the Unit (pin 1 of the DIP switch) selects whether the

Temperature Control Unit will continue operation or stop when the CPU Unit is

in PROGRAM mode.

Terminal Block

Connections

Both inputs and outputs are connected through a terminal block.

Store and Display Data in

BCD or Hexadecimal

A switch on the front of the Unit (pin 3 of the DIP switch) selects whether the

Temperature Control Unit’s data is handled as 4-digit BCD or binary (i.e., 4-

digit hexadecimal.) This switch setting controls both the display format and the

storage format in the memory areas (CIO and DM Areas) used to exchange

data between the CPU Unit and Temperature Control Unit.

Select ON/OFF Control or

PID Control

A switch on the front of the Unit (pin 6 of the DIP switch) selects whether the

Temperature Control Unit operates with ON/OFF control or PID control with 2

degrees of freedom.

Note

The setting on pin 6 sets the control method for all of the Unit’s control loops.

The factory setting is PID control.

Control Methods

• ON/OFF Control

With ON/OFF control, the control output will be ON when the PV is below

the SV. The control output will be OFF when the PV is at or above the SV.

(This control method is used when the Unit is set for reverse operation.)

• PID Control with Two Degrees of Freedom

In earlier versions of PID control, the same controller section controlled

both the response to the SV and the response to disturbances. The weak-

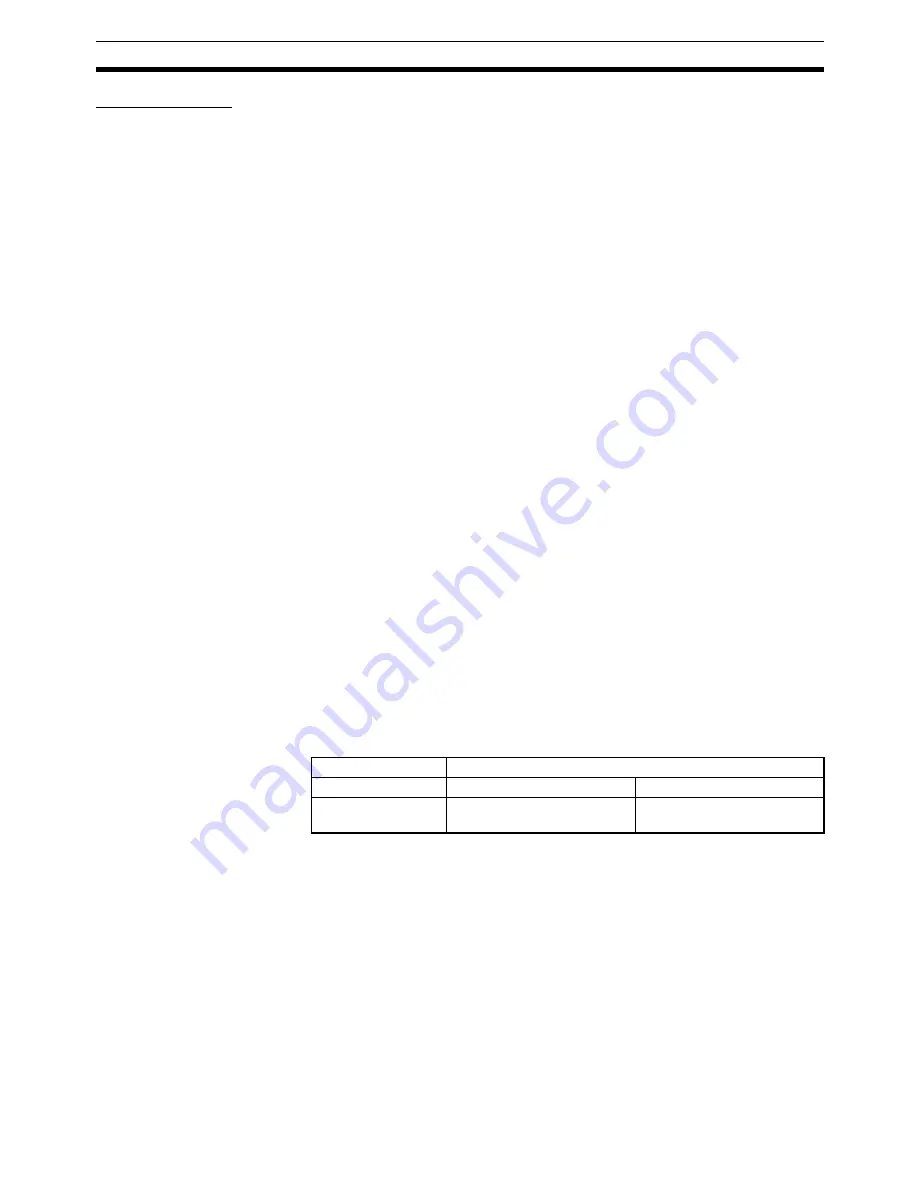

Example

Data storage/display format

Sensor input

Binary (4-digit hexadecimal)

4-digit BCD

K:

−

200 to 1,300

°

C

FF38 to FFFF to 0514

(

−

200 to

−

1 to 1,300)

F200 to 1300

(

−

200 to 1,300)

Summary of Contents for Sysmac CJ Series

Page 1: ...OPERATION MANUAL Cat No W396 E1 03 SYSMAC CJ Series CJ1W TC Temperature Control Units...

Page 2: ...CJ1W TC Temperature Control Units Operation Manual Revised December 2005...

Page 3: ...iv...

Page 5: ...vi...

Page 13: ...xiv...

Page 23: ......

Page 93: ......

Page 105: ......

Page 107: ......

Page 113: ......

Page 115: ......