22

T220UV User Guide

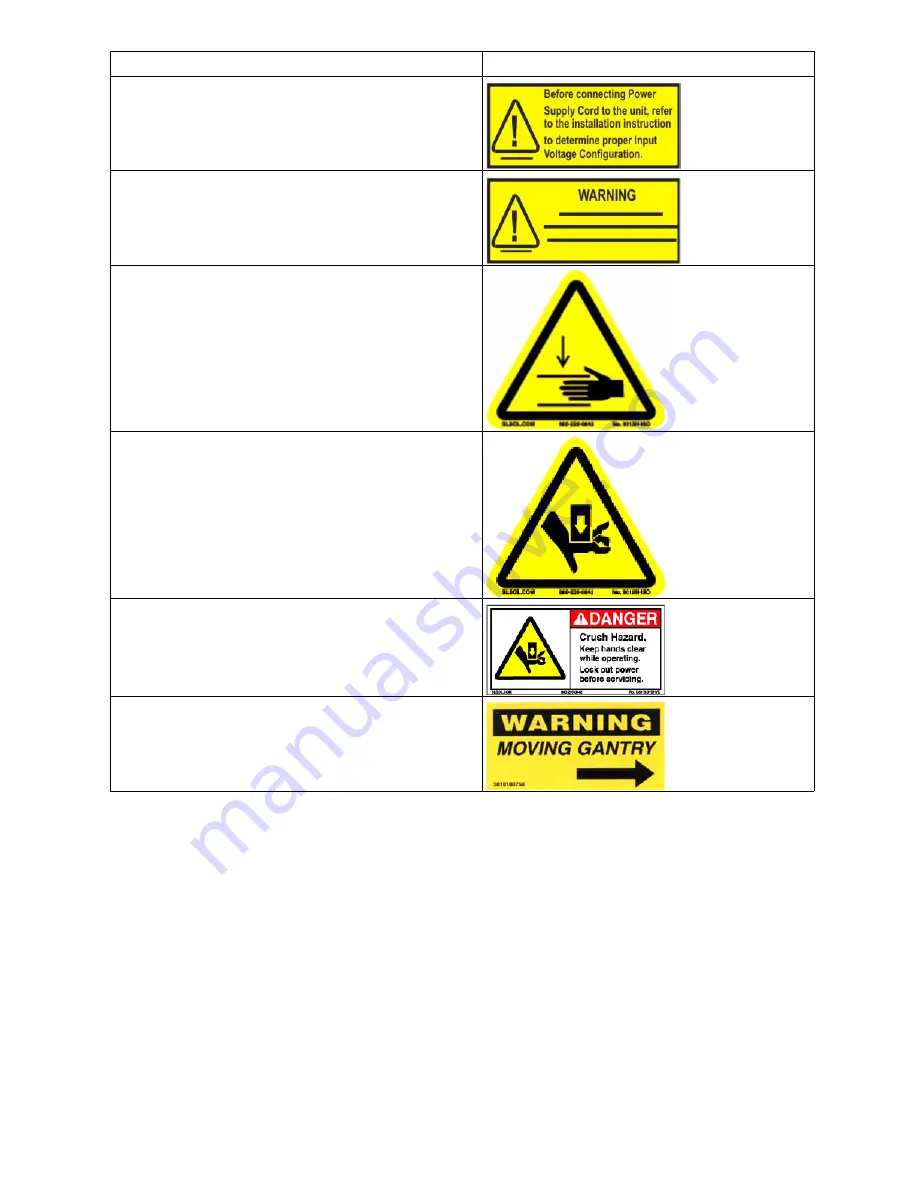

[10] Safety Labels

Before connecting Power Supply Cord to the unit, refer to

the installation instruction to determine proper Input Volt-

age Configuration

WARNING - # 3010100315 HIGH LEAKAGE CURRENT

EARTH CONNECTION ESSENTIAL BEFORE CON-

NECTING SUPPLY.

Located above the AC power cable

Pinch Point - # 3010100726

Located on the bracket endplate and the plate end cap.

Crush Hazard - # 3010100725

Located on the gantry end covers

Danger Crush Hazard: - # 3010100725 Keep hands clear

while operating. Lock out power before servicing

Located on the endplate of the gantry where the carriage rests

on the capping station.

Warning Moving Gantry - # 3010100756

- Located on the ta-

ble to identify the risk involved with the gantry moving during

printing.

Description

Label

Summary of Contents for Arizona T220UV

Page 1: ...Arizona T220UV User Guide...

Page 5: ...5 Arizona T220UV User Guide Chapter 1 Introduction...

Page 10: ...10 T220UV User Guide...

Page 11: ...11 Arizona T220UV User Guide Chapter 2 Product Overview...

Page 15: ...15 Arizona T220UV User Guide Chapter 3 Safety Information...

Page 30: ...30 T220UV User Guide...

Page 31: ...31 Arizona T220UV User Guide Chapter 4 User Interface...

Page 40: ...40 T220UV User Guide...

Page 41: ...41 Arizona T220UV User Guide Chapter 5 How to Operate the Arizona T220UV...

Page 63: ...63 Arizona T220UV User Guide Chapter 6 Ink System Management...

Page 71: ...71 Arizona T220UV User Guide Chapter 7 Media Management...

Page 77: ...77 Arizona T220UV User Guide Chapter 8 Error Handling and Troubleshooting...

Page 92: ...92 T220UV User Guide...

Page 93: ...93 Arizona T220UV User Guide Chapter 9 Printer Maintenance...

Page 114: ...114 T220UV User Guide...