206

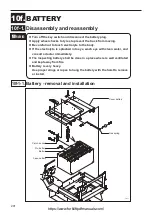

Bracket, sensor

Magnet

sensor

Bracket,

magnet

121W237E

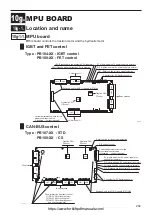

Laser unit

Case

Lock screw

Laser optical axis

ÁLaser pointer unit

121W238E

LASER POINTER (OPTION)

11.

Adjustment

11-1.

1. Raise forks to a height for easy work, and level them.

2. Adjust the positions of the leveling sensor and the

magnet to light on the laser beam.

When the laser beam light on, the fork leveling indicator

is shown on the display.

Either loosen the fixing bolts of the sensor bracket to

reposition it, or slightly adjust the magnet so that it is

in the center of the sensor sensing element when the

forks are level.

<If the forks are not level>

11-1-1. Fork level - adjustment

11-1-2. Laser optical axis - adjustment

Adjustment position

Within

1.0 degree of

the fork leveling position

1. Park the forklift truck face to the pallet.

Distance between the pallet and the tip of the fork

should be about 30 to 50 mm.

2. Level the fork horizontally.

3. Turn on the laser pointer.

Raise the fork to fit to the opening of the pallet.

4. Adjust the angle and height of the laser beam to show

the correct position on the side of the pallet.

If the "LINE" type is used, the laser line should hit the

center of the beam of the pallet.

If the "Dot" type is used, the laser point should hit the

upper board of the pallet..

5. Adjust the axis of the laser light by turning the "Screw,

set" on the side of the laser unit.

6. Make sure if the fork can be inserted into the pallet

normally after indicating the position by the laser

pointer.

https://www.forkliftpdfmanuals.com/