57

20 - Wheel System, Traction

Replacement

1 Clean and repack the bearing cones with axle grease

2 Place the lower bearing back into the hub, and carefully install a new seal to hold the bearing in place

While pressing the seal, take care to press it in straight

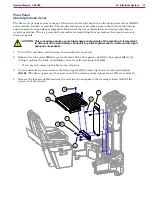

3 If it wasn’t previously done, remove one of the masterlinks that holds the steering chain to the steering

disk If necessary, tie the chain to the disk so it doesn’t get kinked as you are moving the motor

4 Reinstall the steering sprocket

(F)

to the steering shaft Make sure the woodruff key is in position

CAUTION:

Keep your hands and fingers clear of the machine while lowering it onto the drive

wheel. The weight of the machine could crush or sever your hands.

5 Align the steering spindle with the steering hub, and slowly lower the machine, making sure the spindle

is not getting hung up in the spindle

6 Replace the upper bearing cone

(E)

, spacer

(D)

, and castle nut

(C)

a Torque the castle nut to 40±4 lb

•in

(4 5± 5 N

•

m)

b

Loosen the castle nut a minimum of 20 degrees and a maximum of 80 degrees, to align the first

available cotter pin slot with the hole in the spindle

c Install a new cotter pin in the castle nut

7 Press the dust cover

(A)

back on to the top of the hub

8 Rotate the drive wheel so it is pointing directly forward, and rotate the steering wheel so that one of the

spokes is vertical

9 Wrap the steering chain around the steering sprocket

(F)

and back to the steering disk

10 Reinstall the masterlink to secure the chain to the disk Note that the masterlink can be installed facing

up or facing down, which ever is easier to install

11

As necessary, adjust the chain tension. The chain should be snug enough to deflect 1/4” (5mm) in the

gap, but not taught

a Loosen the clamping screw

(L)

b Turn the adjustment and jam nuts

(M)

to adjust the tension

c Retighten the clamping screw