24

04 - Control System

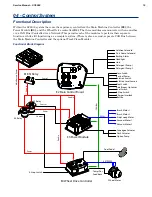

CAN Bus Communication

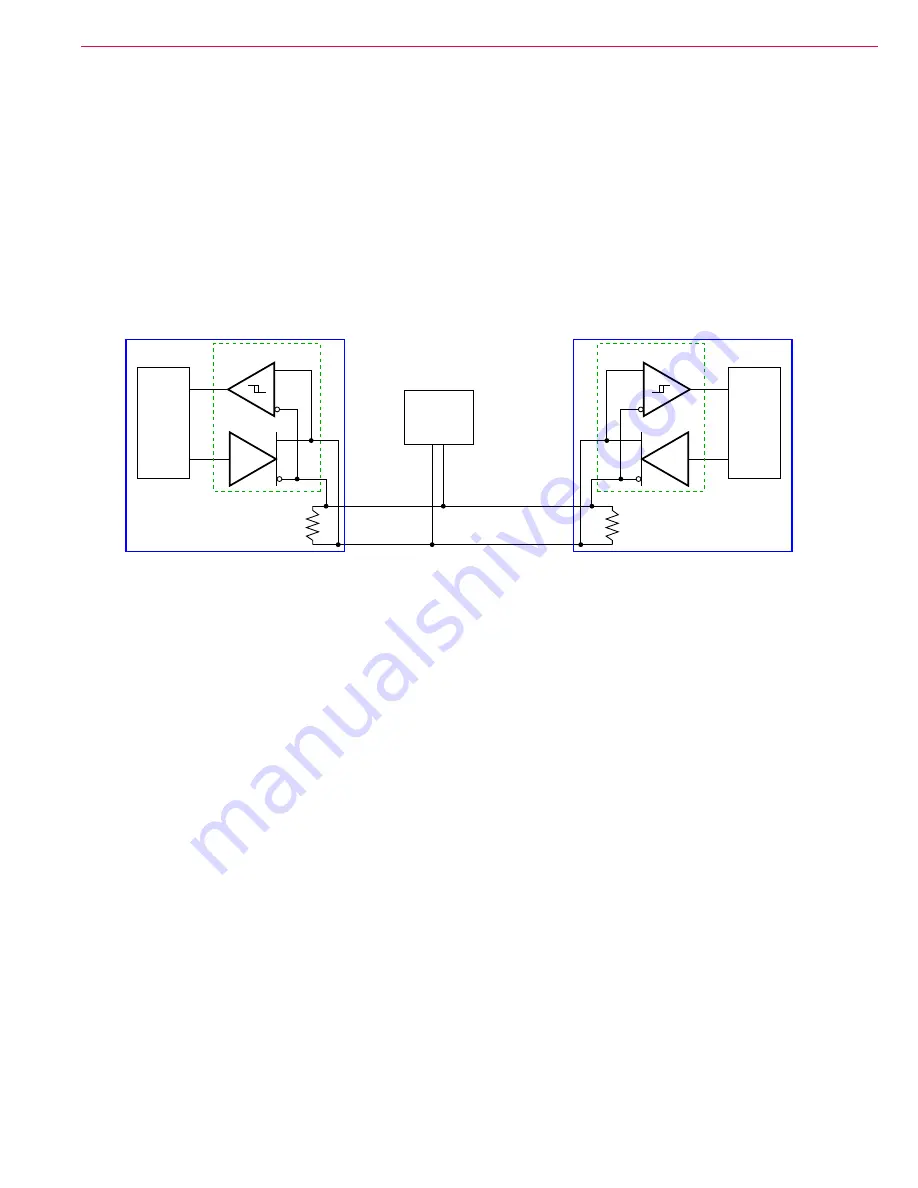

CAN Bus communication was originally created for the automotive industry to allow distributed modules

(Nodes) throughout the vehicle to communicate with each other over a single serial channel without any

single Node being the Master of the communication channel This means that each module broadcasts

what it has to say, and all other modules on the CAN Bus see the message, but pay attention only to those

messages they need to know about

The CAN bus is a twisted-pair of wires running between all of the modules, with one wire being low and the

other wire high, voltage-wise To send a data bit, the module pulls the high and low wires apart, voltage-

wise All of the other modules monitor this to detect a communication message, which is a string of low and

high binary pulses However, the binary logic states are reverse of typical, in that a logic-1 is recessive, and

the difference between CAN

H

and CAN

L

is low (near zero) A logic-0 is the dominant bit, and the difference

between CAN

H

and CAN

L

is high (approximately 2 5 volts)

RX

TX

120 Ω

120 Ω

CAN-L

CAN-H

Controller

CAN Bus

Transceiver

RX

TX

Controller

Transceiver

x-Number of

Additional

Modules

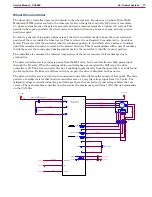

Because none of the modules represent the Master of the bus system, any of the modules can initiate a bus

transmission any time there is not already traffic on the bus. When the module detects inactivity on the bus,

it transmits a dominate bit, and begins sending the message priority level bits But at the same time, it is

also monitoring the bus itself to detect if a higher priority message was being initiated at the same time

The message with the higher priority level will have the bus high for the longest period, and therefore, that

module knows that it is sending the highest priority message The other module ceases its transmission and

waits until the bus is available again

Most CAN Bus messages originate from the Main Controller, or in response to a request from the Main

Controller However, each module can send any emergency messages at any time Below are typical message

sequences for the SC6000 machine

•

Every 250ms, the Main Controller broadcasts the PWM Requested values for the Right Brush, Squeegee

Actuator, Deck Actuator, and Option Pump

• In response, the Power Module broadcasts the actual current flow for each of the above motors.

•

Every 250ms, the Main Controller broadcasts the PWM Requested values for the Left Brush, Side Sweep,

Vacuum 1, and Vacuum 2

• In response, the Power Module broadcasts the actual current flow for each of the above motors.

•

Every 500ms, the Main Controller requests the actual (output) PWM for each of the motors listed above

•

In response, the Power Module broadcasts the actual PWM for each of the above motors

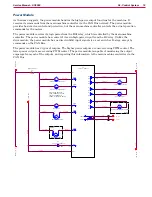

•

Every 100ms, the Main Controller broadcasts drive enable and speed limit messages, and a request for

drive status

•

In response, the Drive Module broadcasts the vehicle speed, motor temperature, motor RPM, throttle

command, throttle pot voltage, and motor current

•

Every 200ms, the Main Controller requests various Drive Controller parameters

•

In response, the Drive Module broadcasts interlock, E-stop, phase A and B encoder position, drive

controller temperature, and temperature cutback %