48

20 - Wheel System, Traction

Functional Description

The drive system of the SC6000 machine

consists of a single drive wheel with an

integral motor The drive wheel connects

to the subframe with a rotational bearing

and flange to provide steering rotation.

Steering control is made through the

steering column that passes through a

universal joint to translate the rotation

from the angled steering wheel to the

vertical shaft and pinion sprocket The

pinion sprocket drives a chain that wraps

around the steering sprocket The steering

sprocket has no chain teeth, but the chain

is fixed to the sprocket at the ends of the

chain using standard master links

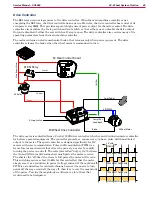

Drive Motor

The drive motor is a 3-phase, remotely commutated, AC induction motor; which is commonly referred to as

a brushless DC motor Even though it is an AC motor, it is powered from a controlled DC power source that

simulates AC power Each of the 3 motor windings is sequentially energized with either zero-volts, positive

battery voltage, or inverted battery voltage. This creates a rotating magnetic field in the windings just like a

normal 3-phase AC motor

Unlike a normal AC motor that just receives blind AC power at a given frequency, the drive motor functions

as a servo-motor, in that the motor provides positional feedback back to the motor driver for the actual

rotor position This is referred to as remotely commutated Two encoders inside the motor report the

actual rotational position of the rotor back to the controller This permits the driver to know which of the 3

windings needs to be energized to rotate the motor in the desired direction, and even position This type of

motor can literally be rotated a fraction of a turn and stopped, if desired

The motor also reports its operational temperature back to the motor driver This is a protection feature to

prevent motor damage due to excessive heat The drive controller can either reduce power to the motor, or if

severe enough, shut down the motor

Drive Pedal Potentiometer

The drive pedal potentiometer (R1 pot) is a variable resistor connected to the Pin J4-16 input of the drive

controller, with pins J4-15 and J4-18 as reference voltages As the resistance changes, the drive controller

increases or decreases drive motor speed

The drive pedal is set up in what’s called a wig-wag configuration, where drive direction is controlled by

a single potentiometer When the throttle potentiometer is in the center position, the wiper voltage is

approximately 2 8 volts The speed controller interprets any voltage between 2 3V and 3 3V as neutral

and the output to the motor will be zero Forward or Reverse movement of the drive pedal rotates the

potentiometer shaft and the wiper voltage is increased for forward travel, or decreased for reverse travel

The magnitude of the voltage difference away from the neutral point also determines the speed that the

motor will be driven

To allow for minor variation in the pedal returning to the neutral position, the drive controller establishes

a deadband around the 2 8-volt center This results in a plus/minus range of voltages where the controller

assumes the pedal is still in the neutral position The deadband for this drive controller (2 3 to 3 3 V) is set

in the machine’s firmware, and is not adjustable.