13

03 - General Information

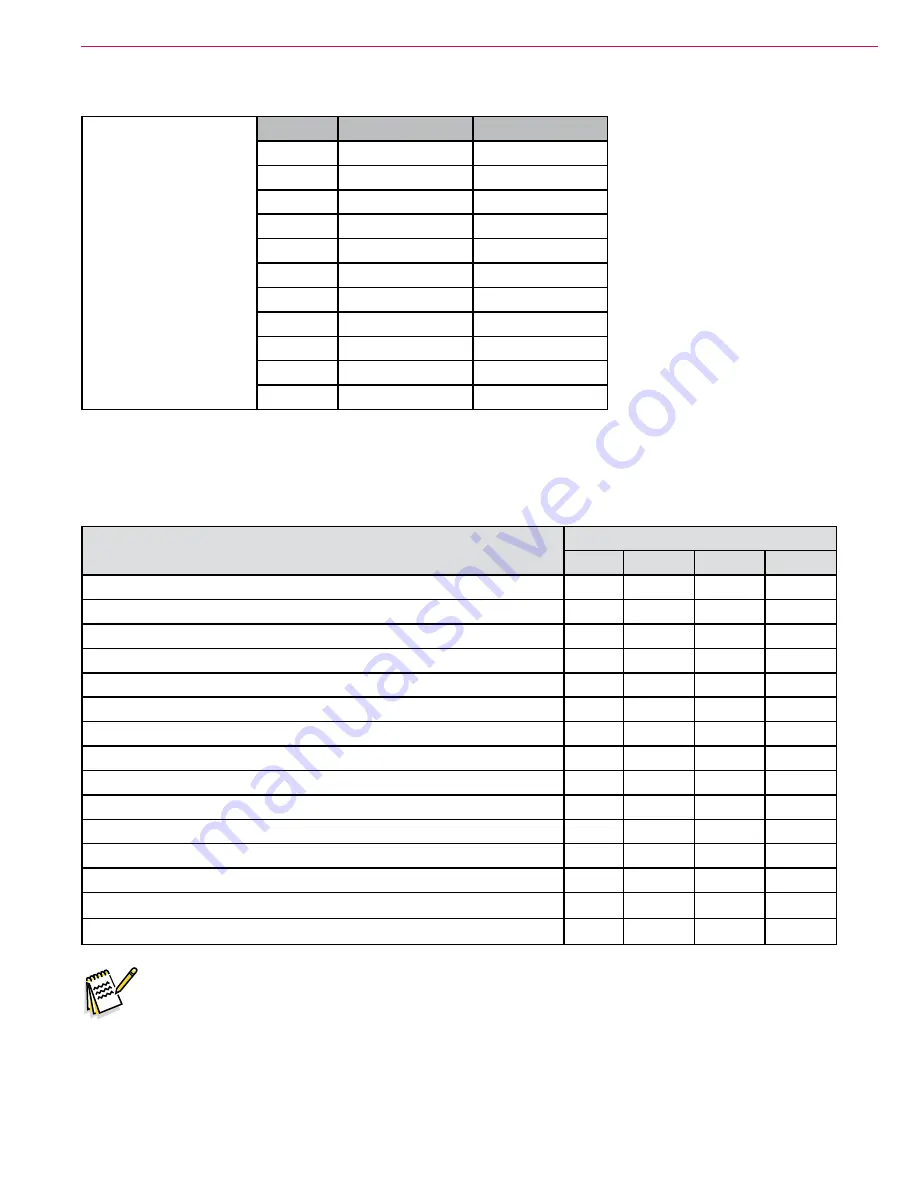

Fastener Torque Specifications

Standard Torque

Specifications (unless

otherwise specified)

Size

Plated Steel

Stainless Steel

#10

42 in.-lb.

28 in.-lb.

1/4“

100 in.-lb.

67 in.-lb.

5/16”

17 ft.-lb.

11 ft.-lb.

3/8”

31 ft.-lb.

20 ft.-lb.

1/2”

75 ft.-lb.

50 ft.-lb.

3/4”

270 ft.-lb.

180 ft.-lb.

M5

61 in.-lb.

36 in.-lb.

M6

9 ft.-lb.

62 in.-lb.

M8

22 ft.-lb.

13 ft.-lb.

M10

44 ft.-lb.

25 ft.-lb.

M12

70 ft.-lb.

40 ft.-lb.

Maintenance Schedule

Maintenance intervals given are for average operating conditions Machines used in severe operational

environments may require service more often

Maintenance Item

Interval

Daily

Weekly

Monthly

Yearly

Charge Batteries

•

Check/Clean Tanks & Hoses

•

Check/Clean/Rotate the Brushes/Pads

•

Check/Clean the Squeegee

•

Empty/Clean Debris Catch Tray in Recovery Tank

•

Check/Clean the vacuum motor foam filter

•

Clean Hopper on Cylindrical System

•

Check Battery Cell Water Level (does not apply to gel cell batteries)

•

Inspect Scrub Housing Skirts

•

Inspect and clean Solution Filter

•

Clean Solution Trough on Cylindrical System

•

Purge Detergent System (if present)

•

Lubricate the Machine

•

Check Vacuum Motor Carbon Brushes (replace motor at 2000 hrs)

1200 Hrs

Check Brush Motor Carbon Brushes

•

Note:

See the individual machine system sections for maintenance information.