EDH0162En1040 – 06/99

8.26

MM4005

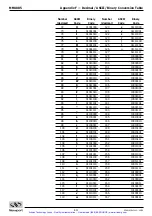

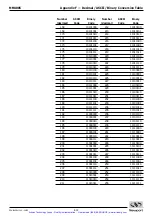

Appendix D — Motion Program Examples

2PR3,SE,WS

Set relative destination of axis #2 3 mm away from

current position; start motion on the synchronized

axis; wait for motion to complete.

1YA1

Increment variable #1 by 1.

WE

End while loop.

1PA6.65,2PA12.5,SE,WS

Set destination of axis #1 to 6.65 mm and of axis #2

to 12.5 mm; start synchronous motion; wait for

motion to complete.

1PA6.5, SE,WS

Set destination of axis #1 to 6.5 mm; start synchro-

nized axis; wait for motion to complete.

2PA9.521,SE,WS

Set destination of axis #2 to 9.521 mm; start synchro-

nized axis; wait for motion to complete.

1PR-0.5,2PR0.596,SE,WS

Set relative destination of axis #1 at -0.5 mm and of

axis #2 at 0.596 mm away from current position; start

synchronous motion; wait for motion to complete.

2PA12.5,SE,WS

Set destination of axis #2 to 12.5 mm; start synchro-

nized axis; wait for motion to complete.

1PA5.5,SE,WS

Set destination of axis #1 to 5.5 mm; start synchro-

nized axis; wait for motion to complete.

2PA10.712,SE,WS

Set destination of axis #2 to 10.712 mm; start syn-

chronized axis; wait for motion to complete.

1PR-0,5,2PR0.596,SE,WS

Set relative destination of axis #1 at -0.5 mm and of

axis #2 at 0.596 mm away from current position; start

synchronous motion; wait for motion to complete.

2PA12.5,SE,WS

Set destination of axis #2 to 12.5 mm; start synchro-

nized axis; wait for motion to complete.

1PA4.5,SE,WS

Set destination of axis #1 to 4.5 mm; start synchro-

nized axis; wait for motion to complete.

2PA11.904,SE,WS

Set destination of axis #2 to 11.904 mm; start syn-

chronized axis; wait for motion to complete.

1PA4,2PA12.5,SE,WS

Set destination of axis #1 to 4 mm and of axis #2 to

12.5 mm; start synchronous motion; wait for motion

to complete.

8CB

Set I/O bit #8 low; this will lift the pen up.

1SY0,2SY0

Declare axes #1 and #2 non-synchronized.

4QP

End of program; quit programing mode.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com