EDH0162En1040 – 06/99

8.22

MM4005

Appendix D — Motion Program Examples

Before starting to write the actual program, we need to consider one more

thing: to assure a good result, the glue must start being dispensed while

the motion is in progress. Thus, we have to start the motion first and then

turn on the dispenser.

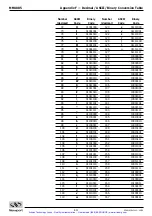

The motion we decide to perform is shown in Fig. D.4.

Fig. D.4

— Desired Motion Result.

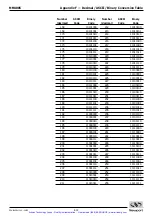

The program will have the following listing:

3XX

Erase program #3, if it exists.

3EP

Enter programming mode and store all entries as

program #3.

CB

Clear all output I/O bits; set all bits to zero.

1PA0,2PA0,WS

Move axes #1 and #2 to absolute position 0 mm;

wait for all axes to complete motion.

1VA4,2VA4

Set velocity of axes #1 and #2 to 4 mm/sec.

1AC8,2AC8

Set acceleration of axes #1 and #2 to 8 mm/s

2

.

1PA14

Move axis #1 to absolute position 14 mm.

1WP2,3SB

Wait for axis #1 to reach position 2 mm; set bit #3.

1WP12,2PA10

Wait for axis #1 to reach position 12 mm; start axis

#2 and move to position 10 mm.

2WP8,1PA0

Wait for axis #2 to reach position 8 mm; start axis

#1 and move to position 0 mm.

1WP2,2PA0

Wait for axis #1 to reach position 2 mm; start axis

#2 and move to position 0 mm.

2WP2,1PA4

Wait for axis #2 to reach position 2 mm; start axis

#1 and move to position 4 mm.

1WP2,3CB

Wait for axis #1 to reach position 2 mm; clear bit #3.

3QP

End of program #2; quit programming mode.

Axis #1

Axis #2

R 2 mm

14, 0

0, 0

14, 10

0, 10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com