01/08 AWB2190-1430GB

Device operation

55

Device operation

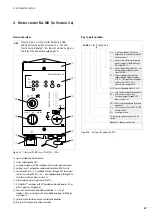

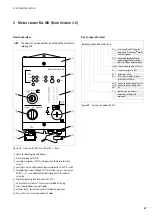

Motor control unit RA-MO is supplied ready for connection. It

allows the direct operation of a 0.09 to 3 kW, 400 V 50 Hz motor

(on RA-MO V1.x: 0.18 – 2.2 kW) without special technical

knowledge.

You can set the following operating modes with key-switches:

• Manual (setup, commissioning, maintenance). In this mode, the

motor can also be operated without PLC.

• Auto (continuous operation through AS-Interface

®

control).

Enable with preselected direction.

• Off or Reset. In switch position Off the contactor actuation is

interrupted and the drive is switched off. At the same time,

setting the switch to Off resets any fault identified by the

RA-MO, such as motor overtemperature (thermistor required) or

overload. Faults are indicated by the red LED in the motor

symbol and signalled through AS-Interface

®

.

Functions through AS-Interface

®

In addition to the normal control functions, Clockwise Operation

and Anticlockwise Operation and signals Automatic Operation

and Group Error, sensor signals assigned to the drive can be read

and internally processed. The configurable quick stop allows

precise stopping, for example on connection points and (eccentric

elevating platforms). Interlocked manual mode can prevent

damage to the conveyed material and the plant in also manual

operation.

With RA-MO from version 2.x you can also perform a Reset and

read out a detailed diagnostics status through AS-Interface

®

.

This allows preventive maintenance and simplifies servicing,

From version 2.2 you can also use specify whether monitoring of

the motor plug (thermistor monitoring) is part of the Group error

or Ready signal.

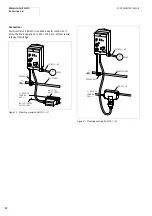

Commissioning the drive

X

Key-switch in "OFF" position

X

Selector switch REV-OFF-FWD in Off position

Before commissioning the motor control unit, make sure that the

motor is correctly connected and the motor cable is plugged in.

The plug M12 to the AS-Interface

®

connection must be live. The

LED ASi-POWER is lit.

Before commissioning, the motor’s current value must be set with

the DIP switch (

section “Setting the functions with DIP

switches/jumpers”, page 60). This ensures that the motor is also

protected against overload during commissioning. When the

mains cable is connected, the load switch (disconnect control unit

RA-DI) then applies mains voltage. LED display UV on the motor

symbol indicates readiness for operation. A lit red LED in the motor

symbol indicates a group fault.

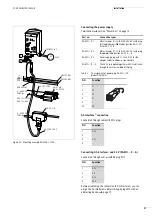

Error handling

X

Set the key-switch in the OFF position.

X

Check the DIP switch position (

On version 1.x devices, pull and reconnect the mains plug after

changing the DIP switch settings. On version 2.x devices the

new DIP switch settings take effect immediately.

X

Check whether

– the motor plug is plugged in.

– the thermistor is correctly connected or whether wires 6 and

7 are bridged in the motor terminal board (

a

fig. 55 and

fig. 56, page 53)

– the motor is overloaded or too hot

– there is a short circuit or an overload of sensor inputs I3 or I4

or actuator output O3.

X

Key-switch in "HAND" position

X

Selector switch REV-OFF-FWD is used to enable forward (FWD)

and reverse (REV) operation. The current selection is indicated

by LEDs REV and FWD on the motor symbol.

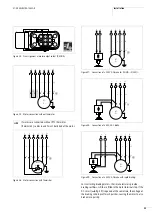

Safety-relevant power off

RA-MO features a safety power-off function up to Category 2

according to EN 954-1. By isolating the 24 V at the infeed

position, all RA-MO devices on one busbar run are switched off. To

activate this function, I/O error signalling must be enabled for all

RA-MO units on the busbar run,

i

Warning!

Do not disconnect the motor and power plugs while they

are live.

j

Warning!

To avoid unexpected starting after a power failure, take

the following steps:

• In automatic mode, 24 V DC or 400 V AC:

Disconnect the 24 V or 400 V and reset the actuation

command in the PLC.

• In manual mode, 24 V DC:

If a direction of rotation has been selected, the drive

does not automatically restart when power is restored.

The direction LED flashes. To continue manual

operation, a Reset command must be issued (key-

switch to OFF).

• In manual operation, 400 V AC:

Activate function “Monitoring lower current limit only

in Manual mode“ (

400 V AC fail with this setting, a group fault is

generated.

Observe the current limit values on page 59.

Summary of Contents for Rapid Link

Page 10: ...01 08 AWB2190 1430GB 6 ...

Page 40: ...01 08 AWB2190 1430GB 36 ...

Page 48: ...01 08 AWB2190 1430GB 44 ...

Page 70: ...01 08 AWB2190 1430GB 66 ...

Page 146: ...01 08 AWB2190 1430GB 142 ...

Page 162: ...01 08 AWB2190 1430GB 158 ...