937A Multi-Sensor System

A.2

Managing Contamination in a Cold

Cathode Sensor

Do not operate at pressures above 10

-3

Torr for extended periods as this will

increase the likelihood of contamination.

If pressure readings appear to be erratic, the Sensor tube may be

contaminated. Inspect it visually. If contamination is visible, you should

replace the internal components with an Internal Rebuild Kit (see

Accessories, p.67).

Depending on the degree of contamination and application, the internal parts

may be cleaned (see Cleaning the I-MAG Sensor, page A.3).

Testing a Cold Cathode Sensor

HPS cold cathode sensors contain the anode and cathode (collector)

electrodes. Test the sensor with an ohmmeter. There should be no shorts

between the electrodes or from the electrodes to the sensor body.

Series 423 I-MAG

®

Cold Cathode Sensor

Connecting the I-MAG Sensor

Mount the Sensor to a grounded vacuum system.

If the I-MAG Sensor has a CF flange, remove the magnet first to allow

clearance for bolt installation. When replacing the magnet, note that it is

keyed to the sensor body to protect the feedthrough pins from damage. The

pins should be straight and centered.

For grounding, use a conductive, all-metal clamp to mount a KF 25 or KF 40

flanged sensor body.

Connect the cable to the Sensor and to the Series 937A Controller before

turning on your system. Tighten the thumb screw on top of the cable to make

sure it is securely in place.

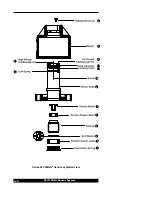

For the following section, please refer to the figure shown on

page A.4.

Disassembling the I-MAG Sensor

Tools required: clean tweezers; clean smooth-jaw, needle-nose pliers

1

Turn Power off to the Series 937A Controller.

2

Loosen the thumb screw on top of the sensor cable and

remove the cable.

3

Loosen the two

flat head screws .

15