62 / 72

HBC-series V7 LV+MV

Maximal revolution of the output shaft Settings

For setting of Maximal revolution of unloaded motor (view from the motor, not mechanics of the system) necessary make following steps.

Set these parameters values by program

Controller 2

(obligatory data):

Parameter P50

–

max. requested rpm limit

(on the gear output),

RR

Parameter P47

– number of motor poles

PP

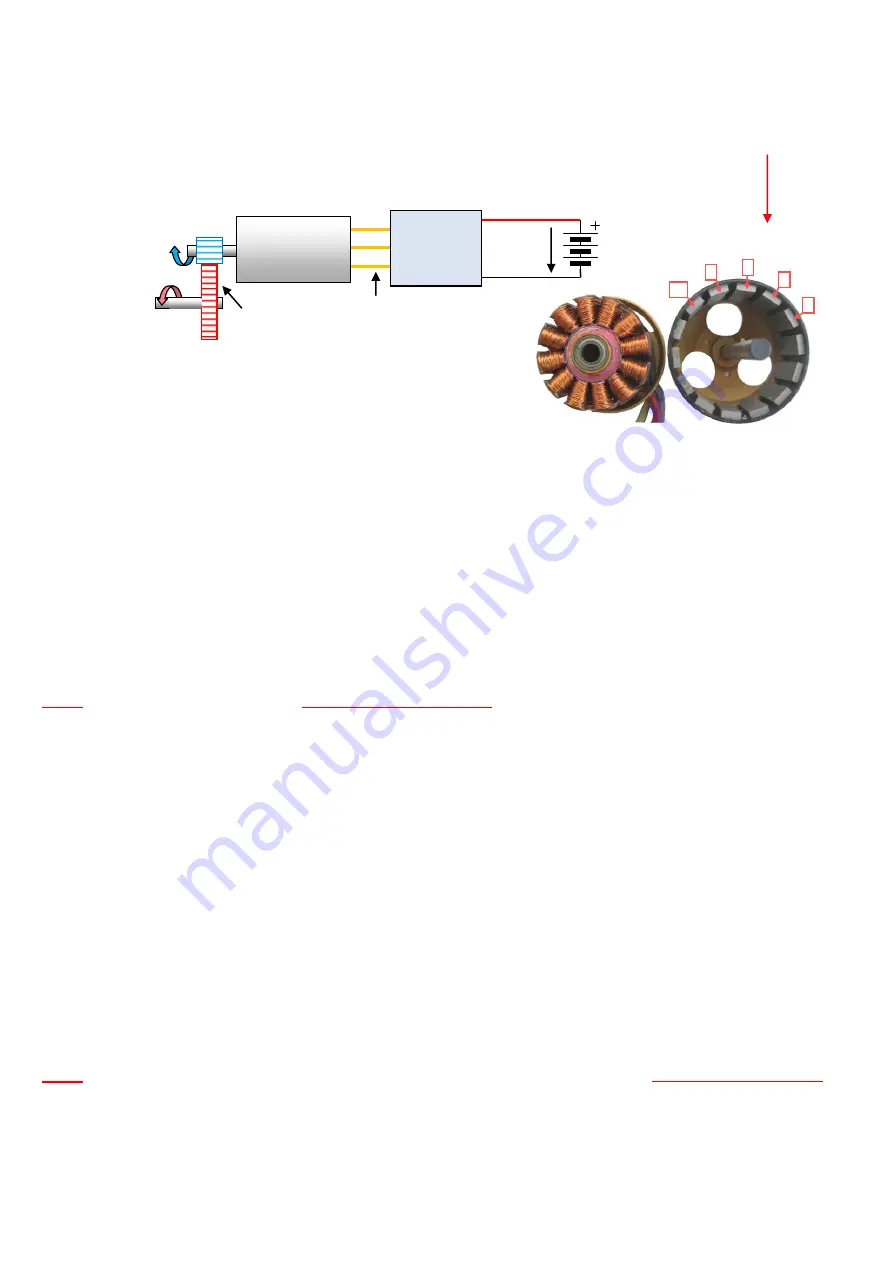

(determined every correct motor producer or you can count magnets, see picture)

Parameter P48

– gear ratio of gearbox

G

By these steps you have set maximal revolution. This settings is also revolution of 3

rd

throttle (flight mode

≡3) for HELI mode #2.

We recommend make checking, if controller range of rpm (electric) is sufficient as well as if motor choice is correct:

“Electric revolution

“ of the motor is the same as mechanical revolution only for 2-poles motor. Motors with higher number of poles have electric revolu-

tion (which must generate controller) proportionally higher (4 poles motor 2x, 6 poles motor 3x, etc.). Controller cannot work with higher revolu-

tion than specified in Technical data (for HBC controllers 250.000 rpm).

ER = RR

x

G

x

PP

/2

(electric revolution)

where:

RR

– requested mechanical revolution on the output shaft (for example helicopter’s rotor, etc.) [ rpm / V]

G

– gear ratio of gearbox

PP

– number of poles of the motor

Result must be <

250.000

rpm. In case of result is higher value, necessary lower gear ratio or use motor with lower number of poles.

Example:

requested mechanical revolution on the output shaft

RR

=

2.000

rpm.

gear ratio is 10 tooth of pinion, 50 tooth of main shaft, i.e.

G

= 50/10 =

5

number of poles of the motor

P

=

12

ER

=

RR x G x PP/2 = 2000 x 5 x 12/2

=

60.000 rpm

Result:

therefore this value 60.000 < 250.000,

controller is suitable for this system.

In next step necessary check motor, if requested output revolution is correct with available voltage.

Requested mechanical revolution of the

motor:

MR

= RR x G

where:

RR

– requested mechanical revolution on the output shaft (for example helicopter’s rotor) [ rpm / V]

G

– gear ratio of gearbox

We recommend this revolution no more than

70 - 80%

of

max. available mechanical revolution of the unloaded

motor (MRM).

In other case

not assurance that system has enough reserve of the power for reliable stabilization of the requested revolution.

Maximal available mechanical revolution of the unloaded

motor:

MRM

=

KV x U

where:

KV

– motor revolution [ rpm / V]

U

– supply voltage [V]

Example:

requested mechanical revolution on the output shaft

RR

=

2.000

rpm.

gear ratio is 10 tooth of pinion, 50 tooth of main shaft, i.e.

G

= 50/10 =

5

Motor

KV

=

800 rpm/V

Max. supply voltage:

(6 x Lipol), i.e. U

=

25,2 V

(charged battery) /

U

=

19,8 V

(discharged battery

– last 20% of energy available)

MR

= RR x G = 2.000 x 5 = 10.000 rpm

MRM

=

KV x U = 800 x 25,2 = 20.160 rpm

(charged battery)

MRM

=

KV x U = 800 x 19,8 = 15,840 rpm

(discharged battery)

Result:

Therefore requested (MM) 10.000 rpm is lower value than 70 - 80% of max. available revolution (=63%),

motor is suitable for this system.

Maximal revolution of the motor Settings

If it is important to limit the engine speed (not the transmission system), you need set only:

Parameter P86

–

max. requested rpm of the motor

MR

Parameter P47

– number of motor poles

PP

(see above)

For maximum engine speed of electrical ER are the same as stated above.

Gear Box

G

=

X:1

Output

shaft revolution

Motor

revolution

Motor

KV

– rpm / V

PP

– number

of poles

RR

MR

Controller

ER

Electric revolution

of the motor

MRM

U

Supply

voltage

(

Helicopter’s

rotor), etc..

Number of poles (magnets)

– for this example PP=14

1

2

3

4

14

Stator

Rotor