44 / 72

HBC-series V7 LV+MV

P52:

Motor timing

(value in ° (angle in degrees))

Automatic timing or 0° is recommended settings for most of the motors. We recommend this setting also in cases when motor producers recom-

mend some concrete angel, for example

10° (this is necessary for some other controllers, not MGM compro).

Automatic timing cannot be the best for some sensorless motors working on the border of its power possibility

– they can lose synchronization.

In these cases is possible set higher timing 10

25°, this can little bit help. However, in these cases, better is used another motor or sensor ver-

sion of choice motor.

P83:

Minimal starting power

Most of the BLDC and similar motors needs some minimum power to overcome the forces that magnets attract (hold) the rotor to the stator pole

bits. If power supplied to the engine is too small (small movement of joystick, a small control voltage, ...), the engine does not exceed these forces

and cannot spin, just vibrates (jerk) here and there.

By setting suitable value for this parameter is eliminated area of insufficient power and to the engine is supplied minimum power needed to spin.

You will avoid engine vibration here and there in the smallest output. For the higher supplied power (according to the control signal), this parame-

ter also does not apply (is not significant).

P54:

Motor basic spin direction (basic direction of rotation)

Correct

Please reverse

By Logic signal

(basic revolution direction is possible change by logic signal on inputs, standard is used port RxD)

This parameters sets the desired direction of motor revolutions without having to swap two motor cables, when the motor is turning the other way. The

same effect as swapping of two motor cables (cables swapping is possible only for sensorless motors).

P48:

Mechanical gear of the system (overall)

Specifies overall gear ratio of 1: X between the engine output shaft and a mechanical output device (i.e. "for transmission). It is important to cor-

rect set (limitation) of the actual mechanical speed of mechanical system, parameter

P50

.

P50:

System rpm limit, for gearbox output shaft

(value in rpm)

This parameter allows to monitor (and not to exceed) the maximum speed of mechanical devices (e.g. propeller, etc.). This is a protection against

mechanics damage by too much speed (rpm). The value of the maximum speed can be entered numerically in the program "

Controller 2

" and is

described in detail in the chapter "

Maximal revolution of the output shaft Settings

In any combination of the output shaft speed, transmission ratio and the number of poles can not revolutions the engine (as defined for 2-pole of

250.000 rpm) exceed this value.

P86:

Motor rpm limit

(value in rpm)

This parameter allows to monitor (and not to exceed) the maximum revolutions of the motor shaft (motor protection).

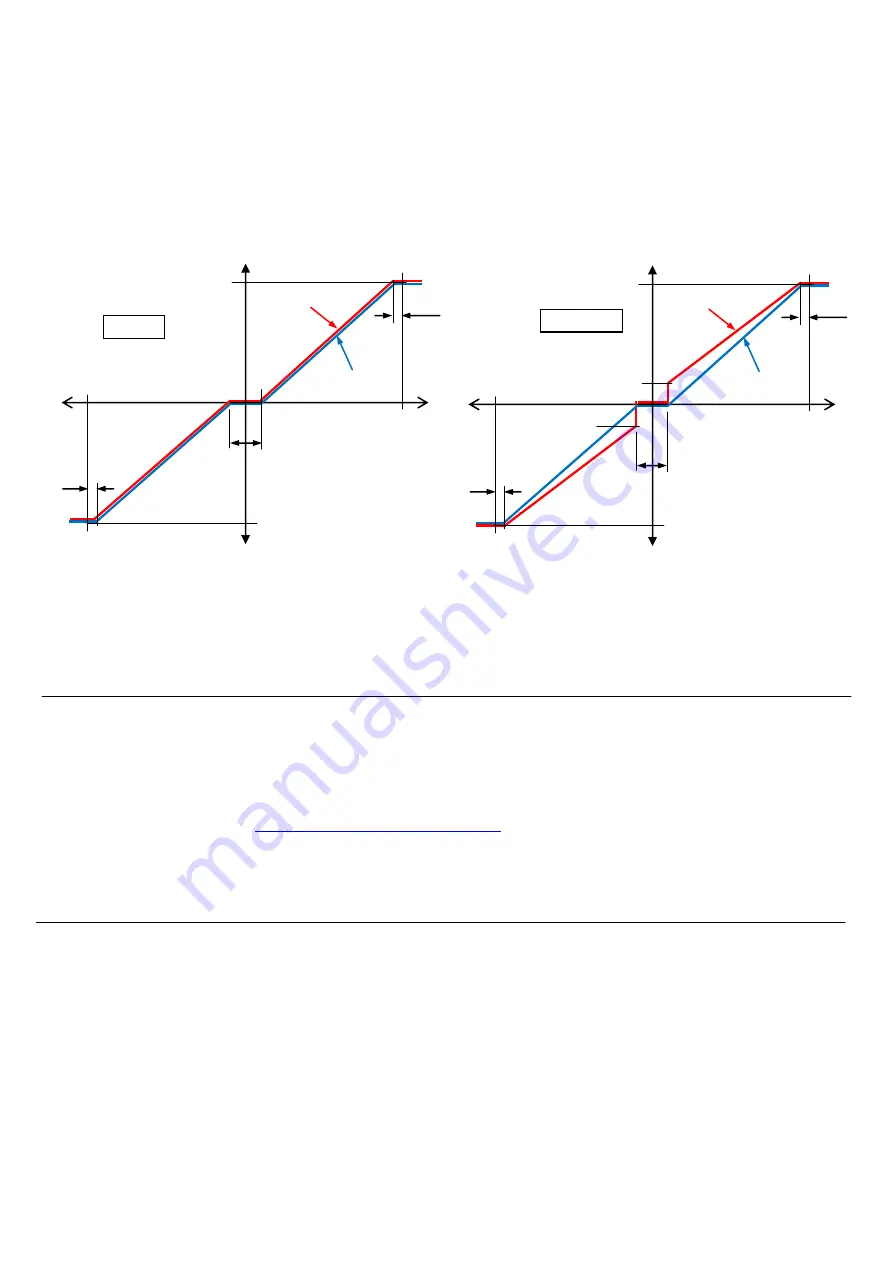

Joystick moving

/ control signal

+100 %

joystick deflection

(control signal)

motor PWM

-100 %

+100 %

-100 %

P83

P12

(neutral width)

P13

P83 = 0

Joystick moving

/ control signal

+100 %

0

motor PWM

-100 %

+100 %

-100 %

P13

P83 = 15%

P13

P13

P83

P12

(neutral width)

joystick deflection

(control signal)