General information

1-39

7510

Go Back

Previous

Next

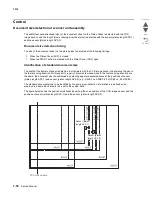

Duplex document

The ADF scans the image on Side 1 (side facing up when set on the tray), inverts the document sheet, scans

the image on Side 2 (side facing down when set on the tray), and then ejects the document sheet while inverting

it.

Therefore, the duplex document sheet is ejected with Side 2 up as with the simplex document sheet.

For two simplex documents, feed is performed in the following sequence.

1.

The first document sheet (Side 1) is fed to the ADF transport roll assembly. (see Pre-feed)

2.

The document sheet (Side 1) is fed to the ADF registration roll assembly and then fed to the scan feed

reference position. (see Pre-registration)

3.

The document sheet (Side 1) is fed at the feed speed corresponding to the selected magnification, and the

image is scanned with the exposure lamp at the scan position. (see Scan control)

4.

As the image is scanned, the document (Side 1) is fed by the ADF feed-out roll assembly and ADF exit roll

assembly that are driven by the ADF registration motor rotating in the reverse direction (CCW direction).

When the trail edge of the document has passed through the sensor (inverter), the ADF registration motor

changes its rotational direction to the normal direction (CW direction) to drive the ADF exit roll assembly in

the opposite direction. Thus, the document sheet is inverted and fed to the ADF transport roll assembly

again.

5.

When the sensor (ADF pre-registration) detects the lead edge of the document sheet (Side 2), the inverter

solenoid assembly is turned on to release the nipped ADF exit roll assembly and exit pinch roll. If these

rolls are not released, the lead edge of the document sheet (Side 2) reaches the ADF exit roll assembly

before the trail edge of the document sheet (Side 2) leaves the ADF exit roll assembly when the document

sheet (Side 2) is long in the slow scanning direction.

6.

The document sheet (Side 2) is fed to the ADF registration roll assembly and then fed to the scan feed

reference position. (see Pre-registration)

7.

The document sheet (Side 2) is fed at the feed speed corresponding to the selected magnification, and the

image on it is scanned with the exposure lamp at the scan position. (see Scan control)

8.

When the trail edge of the document sheet (Side 2) passes through the sensor (ADF pre-registration), the

inverter solenoid assembly is turned off to nip the ADF exit roll assembly and exit pinch roll.

9.

As the image is scanned, the document sheet (Side 2) is fed by the ADF feed-out roll assembly and ADF

exit roll assembly that are driven by the ADF registration motor turning in the reverse direction (CCW

direction). When the trail edge of the document sheet (Side 2) has passed through the sensor (inverter),

the ADF registration motor changes its rotational direction to the normal direction (CW direction) to drive

the ADF exit roll assembly in the opposite direction. Thus, the document sheet (Side 2) is inverted and fed

toward the ADF transport roll assembly again.

10.

At the same time, the ADF feed motor assembly rotates in the normal direction (CW direction) to drive the

ADF transport roll assembly, thus feeding the document sheet (Side 1) toward the exit.

Sensor (ADF pre-registration)

2nd documant

1st document

Summary of Contents for X945E

Page 20: ...xx Service Manual 7510 Go Back Previous Next ...

Page 25: ...Notices and safety information xxv 7510 Go Back Previous Next ...

Page 26: ...xxvi Service Manual 7510 Go Back Previous Next ...

Page 32: ...xxxii Service Manual 7510 Go Back Previous Next ...

Page 88: ...1 56 Service Manual 7510 Go Back Previous Next TTM theory ...

Page 97: ...General information 1 65 7510 Go Back Previous Next 3TM theory ...

Page 104: ...1 72 Service Manual 7510 Go Back Previous Next 1TM theory ...

Page 111: ...General information 1 79 7510 Go Back Previous Next Duplex ...

Page 432: ...3 52 Service Manual 7510 Go Back Previous Next ...

Page 475: ...Repair information 4 43 7510 Go Back Previous Next E F ...

Page 483: ...Repair information 4 51 7510 Go Back Previous Next Connectors A ...

Page 623: ...Repair information 4 191 7510 Go Back Previous Next ...

Page 653: ...Repair information 4 221 7510 Go Back Previous Next ...

Page 714: ...4 282 Service Manual 7510 Go Back Previous Next ...

Page 715: ...Connector locations 5 1 7510 Go Back Previous Next 5 Connector locations Locations ...

Page 720: ...5 6 Service Manual 7510 Go Back Previous Next Printhead Polygon mirror motor ...

Page 725: ...Connector locations 5 11 7510 Go Back Previous Next ...

Page 726: ...5 12 Service Manual 7510 Go Back Previous Next ...

Page 729: ...Connector locations 5 15 7510 Go Back Previous Next Switch media size Switch TTM media size ...

Page 765: ...Parts catalog 7 31 7510 Go Back Previous Next Assembly 29 Electrical 1 3 5 9 2 10 6 4 8 1 7 ...

Page 770: ...7 36 MFP Service Manual 7510 Go Back Previous Next Assembly 32 Electrical 4 2 1 4 3 5 7 6 8 9 ...

Page 797: ...Parts catalog 7 63 7510 Go Back Previous Next Assembly 50 1TM feed unit assembly 4 3 5 4 1 2 ...

Page 802: ...7 68 MFP Service Manual 7510 Go Back Previous Next Assembly 53 1TM drive and electrical ...

Page 804: ...7 70 MFP Service Manual 7510 Go Back Previous Next Assembly 54 3TM covers 3 5 2 4 1 ...

Page 812: ...7 78 MFP Service Manual 7510 Go Back Previous Next Assembly 58 3TM drive and electrical ...

Page 815: ...Parts catalog 7 81 7510 Go Back Previous Next Assembly 60 TTM media trays 3 5 4 3 7 2 6 8 1 ...

Page 824: ...7 90 MFP Service Manual 7510 Go Back Previous Next Assembly 67 TTM drive and electrical ...

Page 828: ...7 94 MFP Service Manual 7510 Go Back Previous Next ...

Page 836: ...I 8 Service Manual 7510 Go Back Previous Next ...

Page 844: ...I 16 Service Manual 7510 Go Back Previous Next ...