General information

1-37

7510

Go Back

Previous

Next

Scan control

Scanning of the image illuminated with the exposure lamp of the full rate carriage is controlled by changing the

feed speed according to the copy magnification.

The document sheet stopping at the scan feed reference position is then fed to the scan position when the scan

signal is sent from the main unit of the machine after the predetermined time lapse following the paper detection

at sensor (ADF registration). Upon receipt of the scan signal, the ADF feed motor assembly rotates in the normal

direction (CW direction) to drive the ADF transport roll assembly and the ADF registration motor rotates in the

reverse direction (CCW direction) to drive the ADF registration roll assembly, ADF feed-out roll assembly, and

ADF exit roll assembly. Each motor gradually accelerates up to the specified speed. When the document sheet

passes the scan position at the specified speed, the images on the document sheets are exposed by scanning

with the exposure lamp of the full rate carriage, and are read by the CCD image sensor assembly.

When the predetermined period of time has elapsed since the document sheet ceased to be detected by the

sensor (ADF pre-registration), the ADF feed motor assembly stops.

When the predetermined period of time has elapsed since the document sheet passed through the sensor (ADF

inverter), the ADF registration motor stops.

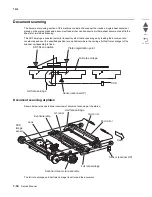

Inversion

In the inversion step, the document sheet is inverted at the inverter gate and fed to the ADF transport roll

assembly again. By thrusting the document sheet against the ADF transport roll assembly at rest, the skew of

the inverted document sheet is corrected.

This enables scanning of a duplex document.

When the predetermined period of time has elapsed since the document sheet passed the sensor (inverter), the

ADF registration motor starts rotating in the normal direction (CW direction) to drive the ADF exit roll assembly in

the direction opposite to the exit direction. Thus, the document sheet is inverted and fed to the ADF transport roll

assembly again.

When the sensor (ADF pre-registration) detects the document sheet, the ADF registration motor decelerates

until it stops.

The inverter gate is so designed that the document sheet fed toward the exit can pass through it smoothly.

When the trail edge of the document sheet has passed through the inverter gate, it closes the downstream

document feed path. Thus the document sheet is fed over the inverter gate up to the ADF transport roll

assembly when fed backward, thereby inverting the document sheet.

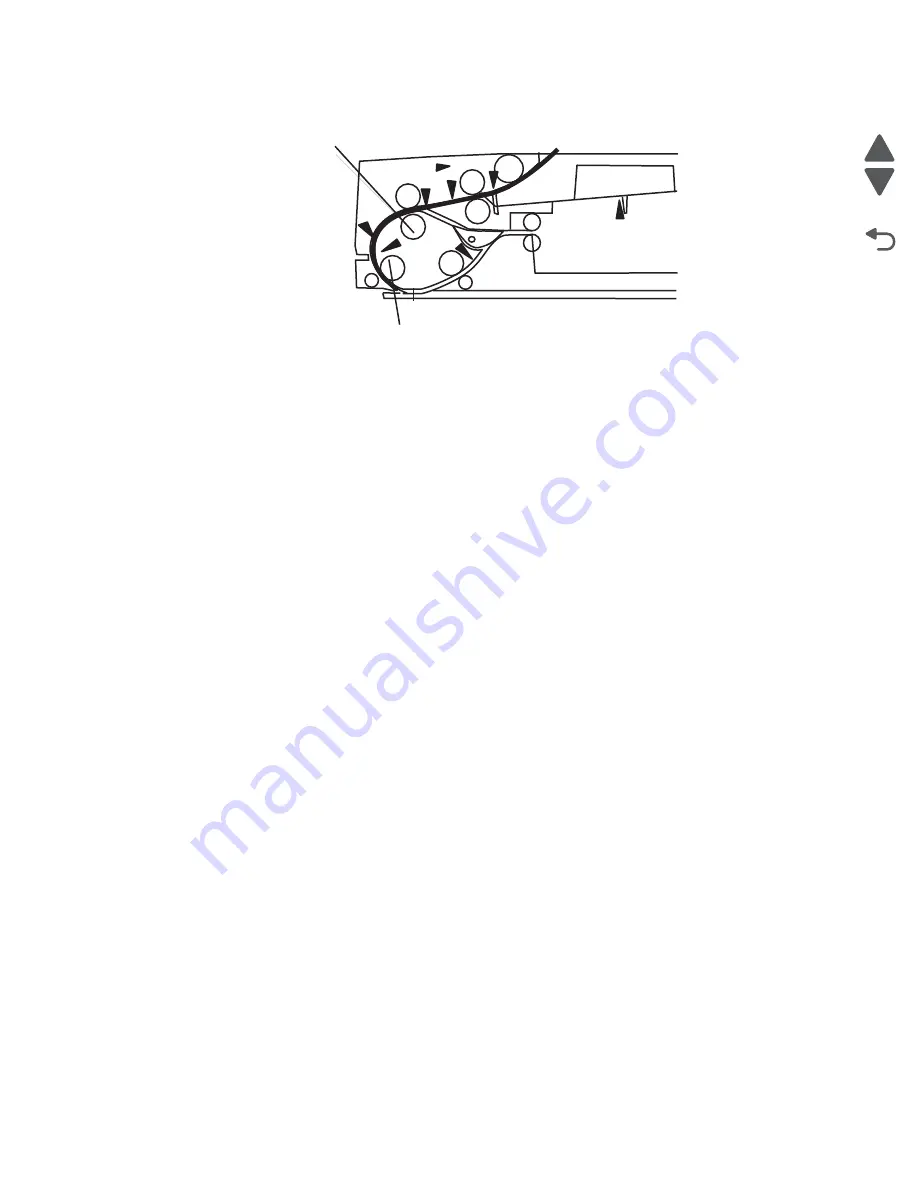

ADF transport roll assembly

ADF registration roll assembly

Summary of Contents for X945E

Page 20: ...xx Service Manual 7510 Go Back Previous Next ...

Page 25: ...Notices and safety information xxv 7510 Go Back Previous Next ...

Page 26: ...xxvi Service Manual 7510 Go Back Previous Next ...

Page 32: ...xxxii Service Manual 7510 Go Back Previous Next ...

Page 88: ...1 56 Service Manual 7510 Go Back Previous Next TTM theory ...

Page 97: ...General information 1 65 7510 Go Back Previous Next 3TM theory ...

Page 104: ...1 72 Service Manual 7510 Go Back Previous Next 1TM theory ...

Page 111: ...General information 1 79 7510 Go Back Previous Next Duplex ...

Page 432: ...3 52 Service Manual 7510 Go Back Previous Next ...

Page 475: ...Repair information 4 43 7510 Go Back Previous Next E F ...

Page 483: ...Repair information 4 51 7510 Go Back Previous Next Connectors A ...

Page 623: ...Repair information 4 191 7510 Go Back Previous Next ...

Page 653: ...Repair information 4 221 7510 Go Back Previous Next ...

Page 714: ...4 282 Service Manual 7510 Go Back Previous Next ...

Page 715: ...Connector locations 5 1 7510 Go Back Previous Next 5 Connector locations Locations ...

Page 720: ...5 6 Service Manual 7510 Go Back Previous Next Printhead Polygon mirror motor ...

Page 725: ...Connector locations 5 11 7510 Go Back Previous Next ...

Page 726: ...5 12 Service Manual 7510 Go Back Previous Next ...

Page 729: ...Connector locations 5 15 7510 Go Back Previous Next Switch media size Switch TTM media size ...

Page 765: ...Parts catalog 7 31 7510 Go Back Previous Next Assembly 29 Electrical 1 3 5 9 2 10 6 4 8 1 7 ...

Page 770: ...7 36 MFP Service Manual 7510 Go Back Previous Next Assembly 32 Electrical 4 2 1 4 3 5 7 6 8 9 ...

Page 797: ...Parts catalog 7 63 7510 Go Back Previous Next Assembly 50 1TM feed unit assembly 4 3 5 4 1 2 ...

Page 802: ...7 68 MFP Service Manual 7510 Go Back Previous Next Assembly 53 1TM drive and electrical ...

Page 804: ...7 70 MFP Service Manual 7510 Go Back Previous Next Assembly 54 3TM covers 3 5 2 4 1 ...

Page 812: ...7 78 MFP Service Manual 7510 Go Back Previous Next Assembly 58 3TM drive and electrical ...

Page 815: ...Parts catalog 7 81 7510 Go Back Previous Next Assembly 60 TTM media trays 3 5 4 3 7 2 6 8 1 ...

Page 824: ...7 90 MFP Service Manual 7510 Go Back Previous Next Assembly 67 TTM drive and electrical ...

Page 828: ...7 94 MFP Service Manual 7510 Go Back Previous Next ...

Page 836: ...I 8 Service Manual 7510 Go Back Previous Next ...

Page 844: ...I 16 Service Manual 7510 Go Back Previous Next ...