2-20

Service Manual

7014-xxx

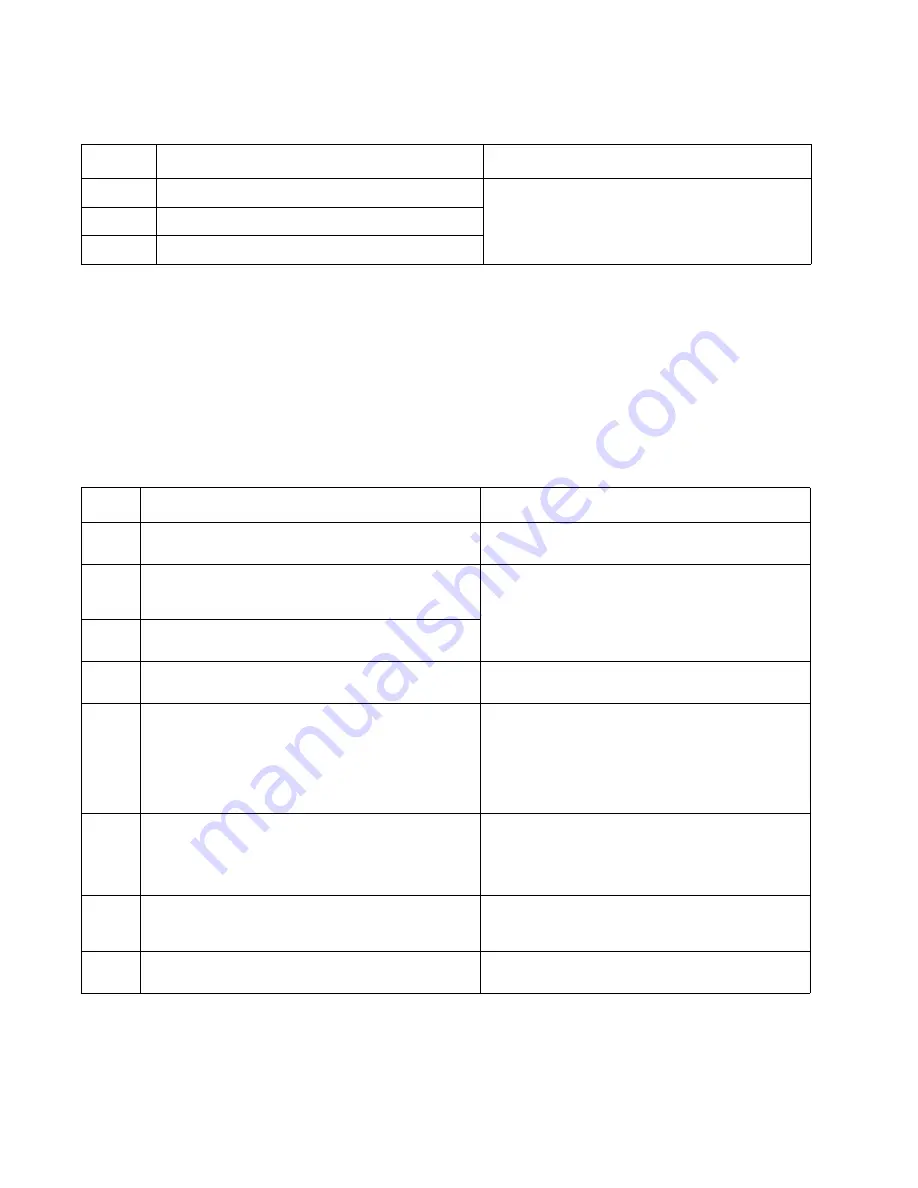

Cartridge error messages

Paper jam error codes (200-series)

Note:

The Event log (See

) will list any of these errors that have occurred.

Repeating jams or jam messages can be caused by any of the following:

•

Faulty/contaminated pick solenoids or worn cams of the solenoids.

•

Faulty/contaminated flags or springs.

•

Debris in the paper path.

•

Media not of the specified length.

•

Faulty media feed clutch. See

“Media feed clutch service check” on page 2-40

Error

Description

Action

30

Invalid refill

Replace the cartridge.

31

Missing or defective cartridge

32

Unsupported print cartridge

Error

Description

Action

200.00

Paper jam around input sensor.

Remove the PC kit and paper or debris at the input

sensor.

200.01

Classic input jam. The media is too long over the input

sensor. Possible causes include multi-sheet feed, tray

size sensing problem, and media slippage.

First, remove the PC kit and paper or debric at the

input sensor. Then, inspect the flag on the input

sensor. It should rotate freely. Replace the sensor if

necessary. Finally, check the paper size settings in

the printer and the driver.

200.02

The main input sensor never became uncovered from

the sheet ahead.

200.03

The video never started on the page at the input

sensor within two inches after hitting the input sensor

Check the printhead. See

200.04

The media at the input sensor before interrupt

occurred–not enough time elapsed since the printhead

started to expect the printhead mirror motor lock.

Possible causes include bouncy sensor or

exceptionally fast pick– perhaps due to media pre-

staged in the source tray.

Carefully remove the tray and notice if the leading

edge of the media is pointed upward and out of the

tray. If so, then inspect the tray wear strips and

replace if necessary.

Inspect the input sensor flag and replace it if it does

not rotate freely or is too loose.

200.06

Imaged page not expected page (bouncy passthru

sensor)

Remove the toner cartridge/PC kit. At the front,

remove the upper front guide, and inspect the flag on

the manual input sensor. If the flag is loose, then

replace it. See

“Media manual input sensor” on

200.08

Media reached the input sensor before the EP was

ready

Inspect the tray for prestaging. Verify the proper

media and inspect the tray wear strips. Replace the

wear strips if necessary.

200.09

Transfer servo never started

Inspect the LVPS/HVPS. See

Summary of Contents for X46 Series

Page 10: ...x Service Manual 7014 xxx...

Page 15: ...Notices and safety information xv 7014 xxx...

Page 16: ...xvi Service Manual 7014 xxx...

Page 22: ...xxii Service Manual 7014 xxx...

Page 162: ...3 56 Service Manual 7014 xxx...

Page 174: ...4 12 7014 xxx 2 Remove the three screws B securing the top of the controller shield B...

Page 184: ...4 22 7014 xxx 6 Remove the screw D from the gear E 7 Remove the plastic bushing F...

Page 194: ...4 32 7014 xxx 2 Carefully pull the scanner front cover away from the tub assembly...

Page 207: ...Repair information 4 45 7014 xxx 5 Remove the three screws B from the left door mount B...

Page 221: ...Repair information 4 59 7014 xxx 7 Open the front access door and remove the lower paper guide...

Page 256: ...4 94 7014 xxx 14 Remove the three screws A from the left rear frame assembly A A A...

Page 278: ...4 116 7014 xxx...

Page 290: ...7 2 Service Manual 7014 xxx Assembly 1 Covers 3 11 7 13 5 16 9 15 2 10 6 17 4 12 8 14 1 17 18...

Page 292: ...7 4 Service Manual 7014 xxx Assembly 2 Imaging 3 11 7 13 5 16 9 15 2 10 6 4 12 8 14 1...

Page 294: ...7 6 Service Manual 7014 xxx Assembly 3 Tray assemblies 3 2 1 5 4...

Page 296: ...7 8 Service Manual 7014 xxx Assembly 4 Electronics 2 1 10 11 12 7 13 9 6 14 2 5 8 3 4 16 15 17...

Page 302: ...7 14 Service Manual 7014 xxx...

Page 306: ...I 4 Service Manual 7014 xxx...

Page 309: ...Part number index I 7 7014 xxx 56P0558 RJ11 Cable w Toroids 7 12 7377732 Relocation Kit 7 12...

Page 310: ...I 8 Service Manual 7014 xxx...