122 Service & Repair

The wear shoes should always be shimmed to allow the carrier to travel in the direction of the side to

side movement, thus aligning the carrier with the cylinders. If the carrier shifts to the right at the

bottom wear shoes, then the following adjustments would be made, depending upon the looseness of

the wear shoes inside the tracks:

Add shim(s) to the left bottom wear shoe

Remove shim(s) from the right bottom wear shoe

Add shim(s) to the right upper wear shoe

Remove shim(s) from the left upper wear shoe

To adjust the wear shoes, apply the following procedure:

1.

Shift the control levers and cycle the unit several

times while observing the wear shoes and action

of the packer and carrier panels. Watch for sideways movement or twisting to determine which

wear shoes must be adjusted.

2.

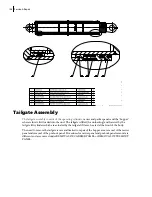

Remove capscrews (1), lockwashers (2), spacers

(3) and cover weldments (4) for both upper

and

lower track holes on each side of the tailgate.

OPERATIONAL STATUS

Truck Running

PTO Engaged

Speed Up On

Transmission Neutral

OPERATIONAL STATUS

Truck Off

PTO Disengaged

OPERATIONAL STATUS

Truck Running

PTO Engaged

Speed Up Off

1

2

3

4

Summary of Contents for 2R-III

Page 1: ...2R III MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...2R III MAINTENANCE MANUAL...

Page 5: ......

Page 6: ......

Page 20: ...10 Introduction...

Page 42: ...32 Safety...

Page 58: ...48 Preventive Maintenance Figure 5 1 Hydraulic tank w return filter 1 2 3 4 5 6 7 8...

Page 66: ...56 Preventive Maintenance...

Page 102: ...92 Troubleshooting...