96 Service & Repair

4.

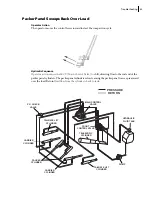

Shift the packer panel lever outward to apply hydraulic

pressure to the case end of the packer

panel cylinders. Hold the lever and observe the fluid flow from the open port on the rod end of

the cylinder. The flow of hydraulic fluid should be no more than 2 fluid ounces per minute. A

flow greater than 2

ounces indicates an excessive piston seal leak. If the cylinder

does not leak

excessively, continue test.

5.

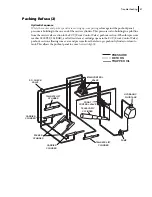

Reconnect the hydraulic lines to the end of cylinder and tighten to 110

ft- lbs. Repeat steps 3-5

for the other cylinder.

6.

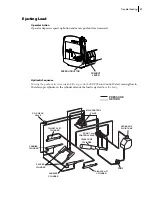

Shift the packer panel lever inward to retract the packer panel cylinder (to the “interrupted-cycle”

position).

7.

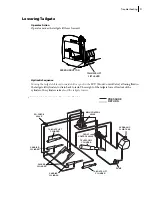

Disconnect and plug the hydraulic lines which connect to the case end of a packer panel cylinder.

OPERATIONAL STATUS

Truck Running

PTO Engaged

Speed Up On

Transmission Neutral

OPERATIONAL STATUS

Truck Off

PTO Disengaged

Caution!

Loosen the hydraulic fittings slowly to release any trapped pressure. Watch for inadvertent

movement of components.

OBSERVE

FLUID

FLOW

PLUG

Summary of Contents for 2R-III

Page 1: ...2R III MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...2R III MAINTENANCE MANUAL...

Page 5: ......

Page 6: ......

Page 20: ...10 Introduction...

Page 42: ...32 Safety...

Page 58: ...48 Preventive Maintenance Figure 5 1 Hydraulic tank w return filter 1 2 3 4 5 6 7 8...

Page 66: ...56 Preventive Maintenance...

Page 102: ...92 Troubleshooting...