Service & Repair 137

Nylon sling, minimum 500 lb. rating

Lint free rags

Petroleum jelly

Parts Required:

Labrie

Plus

part # HYJ4104 - Section Seal Kit, one kit required for each section (does not include

plug or port relief seals)

Labrie

Plus

part # HYJ04107 - Inlet Section Seal Kit, one kit required per valve assembly

Thoroughly clean the valve, connecting hoses and the area directly surrounding the valve.

Valve Removal Procedure:

1.

Remove the hydraulic tank fill cap to relieve any air pressure from the reservoir.

2.

Remove the hoses (label them prior to removal to aid in re-assembly).

3.

Attach the lifting device to the valve using the nylon sling, then using the ¾” socket, 6” extension

and ratchet, remove the four ¾” bolts attaching the valve to the body.

4.

Drain the oil from the valve and set it on a clean, flat surface.

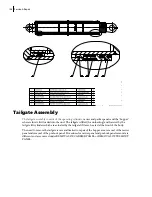

Valve Resealing Procedure:

1.

Using the ¾” socket and ratchet and a ¾” combination wrench, remove the four tie rods holding

the valve assembly together, and remove the tie rods. Thoroughly clean the tie rods, nuts and

washers, and lightly lubricate the threads of the tie rods.

2.

On the inlet section of the valve assembly, use an o-ring pick to remove and discard the old o-

rings, clean the inside face of the plate, and inspect for cracks, abnormal wear, rust or uneven

sealing surfaces. Slide the tie rods through the inlet cover and stand it upward (on end).

Lubricate the o-rings with petroleum jelly and install them into their corresponding seat in the

inlet section. Ensure the o-rings are pushed fully and evenly into their seats.

3.

Starting with the first valve work section, clean the sealing surface of the valve work section, and

inspect for cracks, abnormal wear, rust or uneven sealing surfaces. Carefully lower the valve work

section over the tie rods and mate it to the end plate. Using an o-ring pick remove and discard the

old o-rings. Clean the seats in the o-ring seal face and inspect for cracks, abnormal wear, rust, or

uneven sealing surfaces. Using petroleum jelly, lubricate and install the new o-rings, ensuring

they are seated fully into their corresponding seats.

4.

Repeat step 3 with the remaining valve work sections.

5.

Ensure that the flat sealing surface of the valve end cap is clean and inspect it for cracks, abnormal

wear, rust, or uneven surfaces. Carefully lower it over the tie rods and mate it to the valve work

section. Install the washers and nuts on the tie rods. Using a 3-step torque method, torque the tie

rods to 75 ft-lbs (102 Nm).

6.

Starting with the first valve section, use the ½” socket and ratchet and remove the bolts attaching

the spool actuator to the valve work section. Using the large Phillips driver, remove the 2 screws

attaching the spool eye end dust boot and seal plate; then remove the dust boot and seal plate.

Pull the spool out of the valve work section by grasping the valve spool actuator and gently

pulling it out.

Summary of Contents for 2R-III

Page 1: ...2R III MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...2R III MAINTENANCE MANUAL...

Page 5: ......

Page 6: ......

Page 20: ...10 Introduction...

Page 42: ...32 Safety...

Page 58: ...48 Preventive Maintenance Figure 5 1 Hydraulic tank w return filter 1 2 3 4 5 6 7 8...

Page 66: ...56 Preventive Maintenance...

Page 102: ...92 Troubleshooting...