Service & Repair 113

4.

Remove one roller at a time.

5.

Replace any roller that is excessively worn, cracked

or out of round. Inspect the condition of the

track

bar.

6.

Replacement rollers should be installed with the

original shims or the same amount of new shims

Carrier Roller Adjustment & Maintenance

on page 114). A grease fitting should be installed in

the replacement

roller.

7.

Repeat Step 1 to determine if additional shims are required (see

OPERATIONAL STATUS

Truck Off

PTO Disengaged

OPERATIONAL STATUS

Truck Running

PTO Engaged

Speed Up On

Transmission Neutral

Caution!

Do not over shim rollers. Excessive shimming may damage the tailgate walls or wear the

track channels.

OPERATIONAL STATUS

Truck Off

PTO Disengaged

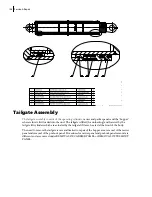

SHIMS

ROLLER

GREASE FITTING

Summary of Contents for 2R-III

Page 1: ...2R III MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...2R III MAINTENANCE MANUAL...

Page 5: ......

Page 6: ......

Page 20: ...10 Introduction...

Page 42: ...32 Safety...

Page 58: ...48 Preventive Maintenance Figure 5 1 Hydraulic tank w return filter 1 2 3 4 5 6 7 8...

Page 66: ...56 Preventive Maintenance...

Page 102: ...92 Troubleshooting...