Step 4: Calibrate the Face Tool

KVAL Operation Manual

3-20

Note:

To help identify tools that need to be calibrated, view

Tool Path Review

.

“About the Tool Path Preview Test Tab” on page 3-20

Tip:

To help isolate tool function, use the

Tool Config

page to disable or enable sus

-

pected tools. After isolating the tool, run the

Door Job

late and Calibrate a Specific Router” on page 3-21

1.

Create a new

Door Job

of a

Lock Cut

of your choice.

2.

Add

Door Job

to the

Queue

.

3.

Once the cut is machined, measure the

length

,

width

, and

depth

positions of the cut.

If the cut is not in the specification, determine which tool and axis needs to be cali

-

brated.

4.

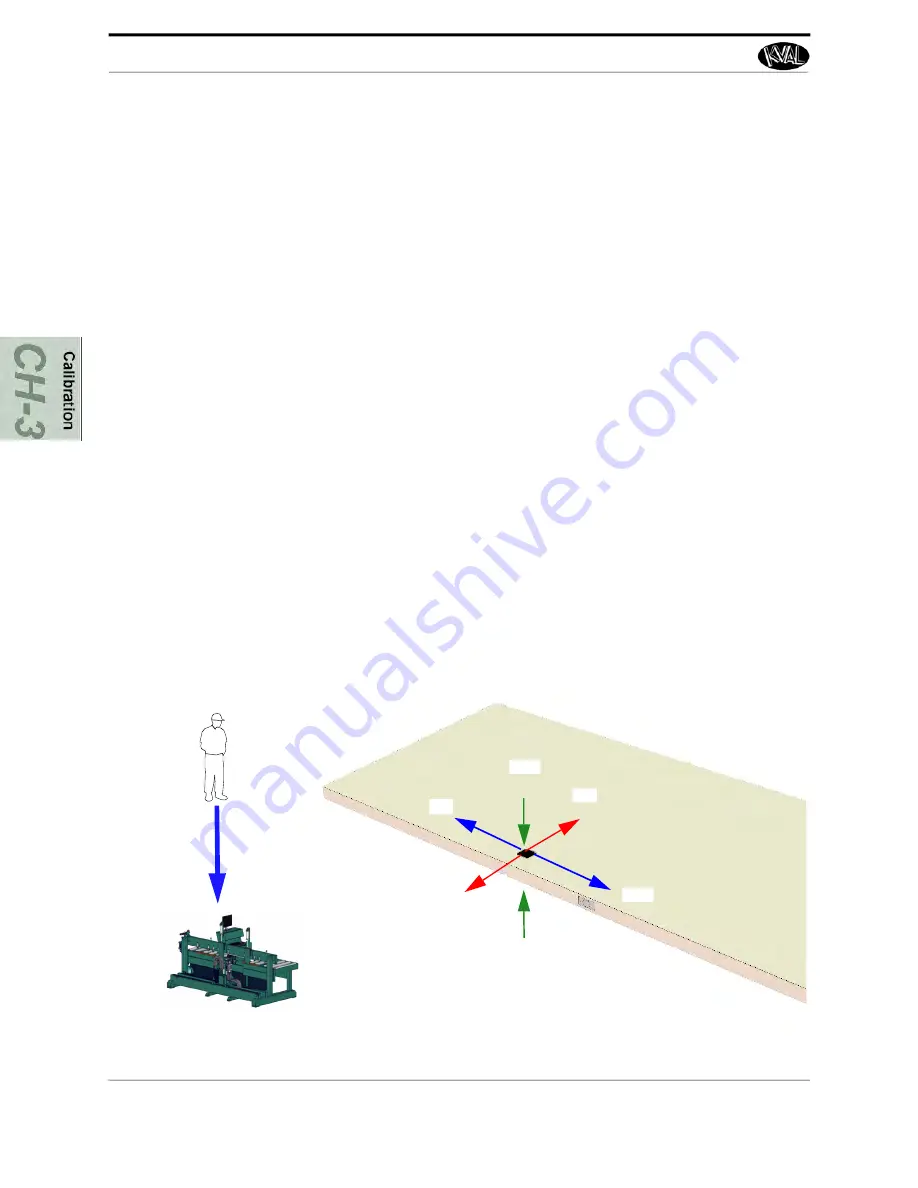

Perform the

Left Hand Rule

pointed at the cut lock to determine axis direction. See

illustration below.

• If

diameters

of the plunges are out of specification, the

Diameter Offset

needs to

be adjusted.

• If the

length

of the cut is out of specification, the

X-Axis

needs to be adjusted.

• If the

width

of the cut is out of specification, the

Y-Axis

needs to be adjusted.

• If the

depth

cut is out of specification, the

Z-Axis

needs to be adjusted.

5.

If not in specification, adjust the location. Repeat until specification is reached.

Face Tools Calibration Reference Cut

The figure below, shows a sample reference cut and the type of offset to input into the calibration

menu.

See “How to Enter Calibration Data” on page 3-7

+

X

+

Y

+

Z

-

X

-

Z

-

Y

Summary of Contents for MLX

Page 59: ...About the Tool Config Tabs 2 29 KVAL MLX Operation Service Manual ...

Page 64: ...Description of the Light Tower KVAL MLX Operation Service Manual 2 34 ...

Page 90: ...System IT Administration KVAL MLX Operation Service Manual 4 4 ...

Page 117: ...Collet Torque Values 5 27 KVAL MLX Operation Service Manual ...

Page 118: ...Collet Torque Values KVAL MLX Operation Service Manual 5 28 ...

Page 141: ......

Page 142: ......

Page 143: ......