About the Tool Config Tabs

KVAL MLX Operation/Service Manual

2-28

About Tool Locations

Tool locations are identified by slots.

See “Carriage Head” on page 2-6

identifications.

Note:

The tool names are factory suggested. Identification of the slots can be altered

through this menu.

About Using Tool Configuration

1.

Identify the tool that needs replacement.Measure tool dimensions and capture the

data. (Use this information to populate the

Drill or Router

pop-up screens).

2.

Select the

Tool Slot

from the desired assembly

3.

Enter the data into the pop-up screen. (Router or Drill)

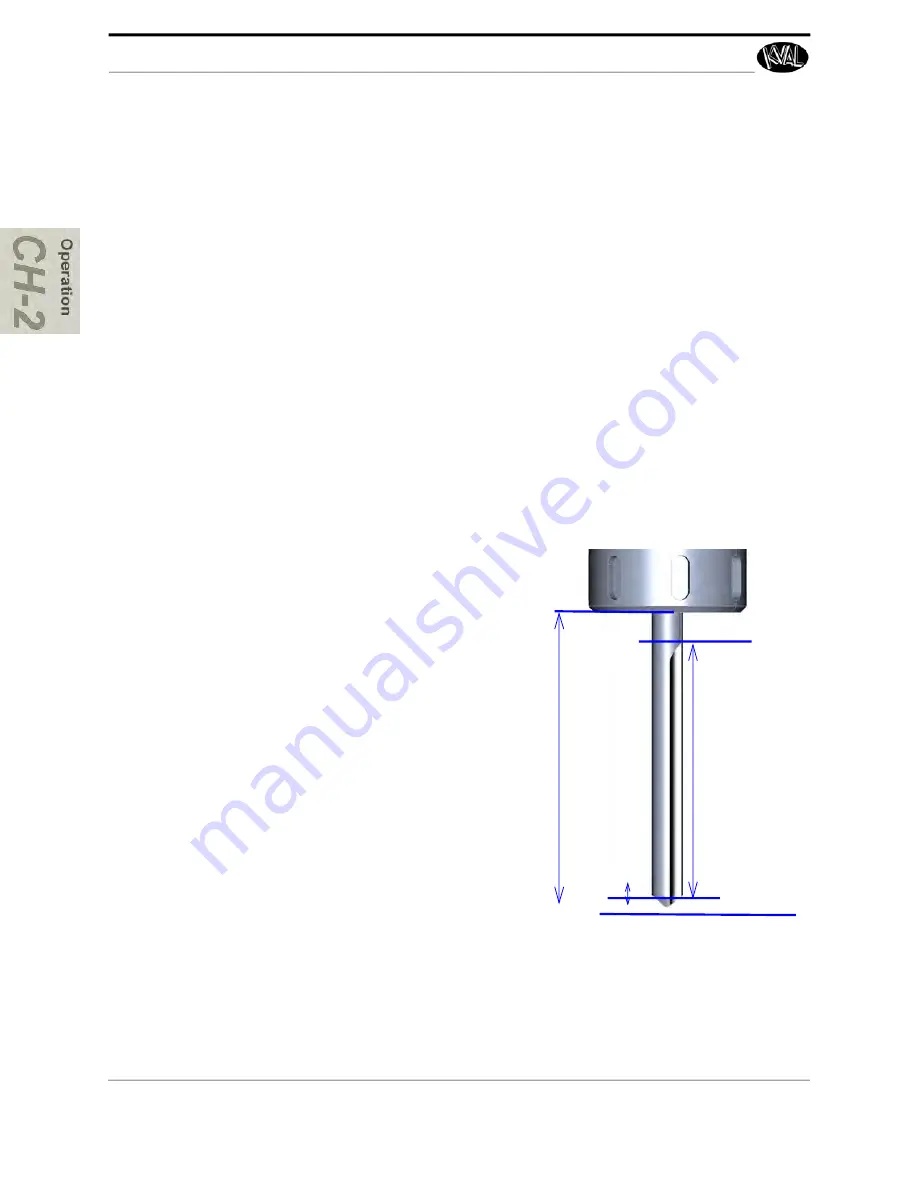

Measuring Tool Length

Important:

The accuracy of the data

Tool Setup Group

is important. Any errors could

damage tooling or product.

About Entering Data into the Pop-up Menu

Insert specifications of the tools being used to make the cuts. Ability to name the tools to user

defined descriptions. Customize the tools to reflect the actual tool parameters, making the most

accurate cuts. Ability to define cut operation.

1.

Measure the parameters listed below:

• Total Tool Length - The distance from the collet

face to the tool’s tip

• Tool Cutting Length - The distance from start of the

cutting area to the tip of the bit.

•

Tool Point Length- From the point where the point

starts to the end of the bi

t.

2.

Update the data in the

Tool Setup Group

.

Tool Point

Length

Cutting

Length

Total Tool

Length

Summary of Contents for MLX

Page 59: ...About the Tool Config Tabs 2 29 KVAL MLX Operation Service Manual ...

Page 64: ...Description of the Light Tower KVAL MLX Operation Service Manual 2 34 ...

Page 90: ...System IT Administration KVAL MLX Operation Service Manual 4 4 ...

Page 117: ...Collet Torque Values 5 27 KVAL MLX Operation Service Manual ...

Page 118: ...Collet Torque Values KVAL MLX Operation Service Manual 5 28 ...

Page 141: ......

Page 142: ......

Page 143: ......