Grease Locations for the MLX

KVAL MLX Operation/Service Manual

5-16

Grease Locations for the MLX

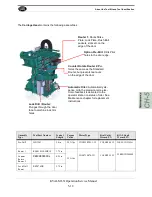

Locations of Bearings on the Carriage Head

For lubrication schedule information,

see “Lubrication Schedule” on page 5-12.

The figure below

shows the bearings of the

Tools

from the front section viewpoint. The bearings are color coded for

easy identification.

1.

Some bearings may be difficult to get access to. Use an extender to reach tight areas.

1.

Perform

Lockout/Tagout

2.

Remove cover.

3.

Identify zerk fittings and apply EP-2 grease.

4.

After lubrication is completed, re-install the cover.

5.

Reverse

Lockout/Tagout

.

FIGURE 6.

Carriage Bearings

This machine is a powerful electro-mechanical

motion control system. If servicing this machine, fol

-

low the safety guidelines. Failure to do so can result in

damage to equipment and/or serious injury to person

-

nel.

Shutdown the machine and follow the

“Lock Out

Tag Out procedures

Caution

Y Axis Bearings:

Bearings move the Cutter Head ver

-

tically up and down.

X Axis Bearings:

Bearings move the Cutter Head

across the machine. Located on the

bottom of the plate.

Z Axis Bearings:

Bearings move the Cutter

Head into the cut.

Tool Bearings:

Check bearings for each tool

Summary of Contents for MLX

Page 59: ...About the Tool Config Tabs 2 29 KVAL MLX Operation Service Manual ...

Page 64: ...Description of the Light Tower KVAL MLX Operation Service Manual 2 34 ...

Page 90: ...System IT Administration KVAL MLX Operation Service Manual 4 4 ...

Page 117: ...Collet Torque Values 5 27 KVAL MLX Operation Service Manual ...

Page 118: ...Collet Torque Values KVAL MLX Operation Service Manual 5 28 ...

Page 141: ......

Page 142: ......

Page 143: ......