NOTICE

• Komatsu genuine fuel filter cartridges use a special filter that has highly efficient filtering ability.

When replacing parts, Komatsu recommends using Komatsu genuine parts.

• The common rail fuel injection system used on this machine consists of more precise parts than

those in the conventional injection pump and nozzles. If any cartridge other than a Komatsu genu-

ine filter cartridge is used, dust or dirt may get in and cause problems with the injection system.

Never use a substitute.

• When performing inspection and maintenance of the fuel system, be careful not to let any dirt or

dust get in, more than ever before. If dust sticks to the fuel system, wash it off thoroughly with fuel.

Items to be prepared

• Container to catch drained oil

• Filter wrench

When replacing the fuel main filter cartridge (every 1000 hours), replace the fuel prefilter cartridge first.

1.

Open the engine side cover on the right side of the ma-

chine.

2.

Place a container under the fuel prefilter cartridge to catch

the fuel.

3.

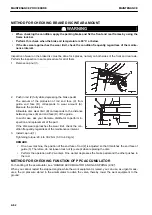

Loosen drain valve (1) and drain water and sediments

from transparent cup (2), and also drain all the fuel from fil-

ter cartridge (3).

4.

Remove drain hose.

5.

Turn filter cartridge (3) counterclockwise by using the filter

wrench, and remove it.

6.

Make sure that drain valve (1), which is provided in the lower part of transparent cup (2) of the new filter

cartridge, is firmly tightened.

Tightening torque: 2.5 to 3.4 Nm {0.25 to 0.35 kgm}

7.

Clean the filter holder and apply thin film of oil to the pack-

ing surface.

Remove filter cartridge cap (A) and install to the filter hold-

er.

8.

Clean the filter head, fill the new filter cartridge with clean fuel, thinly apply oil to the packing surface, then

install it to the filter head.

NOTICE

• When filling the filter cartridge with fuel, do not re-

move cap (A) at the center. Always fill with fuel

from small holes (B) (8 places) on the dirty side.

• After filling with fuel, remove cap (A) and install

the fuel filter.

• Always fill with clean fuel. Be careful not to let any

dirt or dust get into the fuel. In particular, center

portion is the clean side, so do not remove cap (A)

when filling with fuel. Be careful not to let dirt or

dust get into the center portion on the clean side.

MAINTENANCE PROCEDURE

MAINTENANCE

4-50

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......